|

Coeymans (Pronunciation: Quee-mans) is a town in Albany County, in the Albany metro area.

The latitude of Coeymans is 42.473N. The longitude is -73.792W. Elevation is 545 feet.

The population, at the time of the 2000 census, was 8,151.

====================

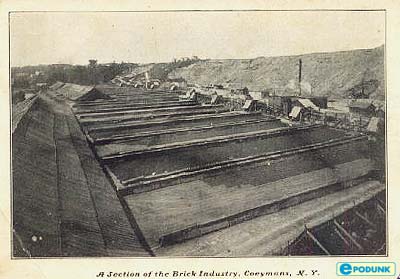

Brick Manufacturers

as listed in "Within These Gates" by Daniel deNoyelles

|

Name of Company Number of Machines The Up-River District Empire Brick & Supply Co., Stockport, NY ................ 15 G. W. Washburn & Co., Catskill, NY ....................... 8 B. Goldin & Son, Catskill, NY ............................ 6 Atlas Building Material Co. Yard No. 2, Hudson, NY ....... 9 Sutton & Suderly Brick Co., Coeymans, NY ................. 4 Sutton & Sinsabaugh, Coeymans, NY ........................ 3 Corwin & McCullough, Coeymans, NY ........................ 2 Ziegler Bros., Coeymans, NY .............................. 3 Powell & Minock, Coeymans, NY ............................ 5 Robert Lent, Coeymans, NY ................................ 4 W., W. Rider, Jr., Athens, NY ............................ 4 Edward Brosseau, Schedack Landing, NY .................... 4 Stuyvesant Brick Co., Stuyvesant, NY ..................... 5 Cary Brick Co., Mechanicsville, NY ....................... 4 |

====================

Coeymans Brickyards: 1850 - 2001

In Brick Manufacturers of the United States, Jim Graves lists the following Coeymans area brick companies: ADAMO'S (James and Joseph)ADAMO BROS (ADAMO B)

BROWER, JOSEPH A. & L.K. 1888 - 1895

CORWIN & McCULLOUGH (C & MC) 1888 - 1910

FEVLIT, HENRY 1895

FOOTIT, H. 1895 - 1900

GORDON, W. (GORDON)

HENDRICK & WALSH 1889 - 1895

HARRIS, SYLVESTER 1850

LEABRIDGE, P. 1850

NILES & SLINGERLAND 1895

POWELL & MINNOCK (P & M) (P & MBW) 1895 - 2001 (see below)

ROAH HOOK BRICK CO. (Roah-Hook) 1905 - 1957

ROUKER 1885

SEABRIDGE, PETER 1850 - 1864

SICKLER, JACOB 1850

SLINGERLAND, H. & CO.1888 - 1895

SUTTON & SINSABAUGH (S & S) 1904 - 1910

SUTTON & SUDERLY BRICK CO. (SSBCO) 1885 - 1957

SUTTON, M.J. & CO. 1888 - 1895

VERNOL, ISAAC & GIBB, SAMUEL 1888

ZIEGLER BROS. (ZZZ) 1905 - 1910

====================

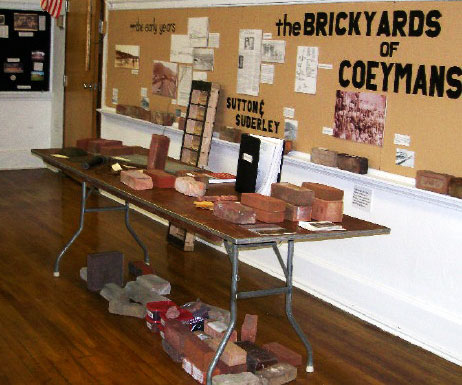

Coeymans Brick on exhibit at the Ravena Coeymans Historical Society Museum

(photo from Ravena Coeymans Historical Society website)

====================

Powell & Minnock

Route 144, 2170 River Road Coeymans, NY (5 machines in 1905) Powell & Minnock Brick Works 1895 - 1967 Div. of Darling 1970 Div. of Marbleh 1972 - 1981 General Dynamics Corp. 1981 - 1985 Powell & Minnock Brick Works, Div. of Isiklar Holding, Istanbul, Turkey 1985 - 2001 P & M Brick LLC, Port of Coeymans Marine Terminal 2001 - present

View Larger Map

By the mid-1970s, the Hudson River brick industry was reduced to 2 plants: Powell and Minnock and the former Hutton Company. The last major investment at Powell & Minnock was a new molded-brick plant, built in 1989. At the time, Powell & Minnock was owned by General Dynamics Corp., the diversified industrial giant known for its manufacture of tanks and submarines.

In 2000 an award from NY State of more than $4,000 went to Powell and Minnock to fund an efficiency study of the facility. Annual energy bills exceeded $1.6 million. The study recommended a number of ways the company could lower its energy costs, including lighting upgrades and retrofits, installing more efficient electric motors, and modifying the kilns used to manufacture the bricks, which would allow 63% more bricks to be processed through the kilns each day. These recommendations could save Powell and Minnock about $640,000 per year. The total cost to implement these recommendations will be a little more than $1 million, which will be covered by the energy savings in less than two years. In 2001 Cockrell and other managers tried to save the company which was then owned by Isiklar Holding of Istanbul, Turkey with a buy-out plan (see below). The plan failed.

P & M was the last brick manufacturer in New York State. Their website stated P&M Brick was "the oldest brick manufacturer in New York State, which manufactures formed and extruded bricks used in building construction." There are records showing as of May 8, 2006, their Gedney Hill Site in New Baltimore and Coeymans was still open as well as a Clay Mine located at 494 Western Turnpike, Altamont, NY In 2006, a portion of the Powell & Minnock site, located to the immediate south of the Lafarge cement plant, was used for assembly of New York City's 145th Street Bridge's new swing span.

Hudson Valley Ruins, by Thomas E. Rinaldi and Robert J. Yasinsac.

"Hudson Valley Ruins tells of the factories, railroad stations, quaint estates, department stores, brickyards and other historic structures near its banks that are now threatened by redevelopment and argues elegantly and persuasively that we need to save them. Bravo." from The Business Review, Albany, October 19, 2001:Managers try to save state's last brick worksby William TuthillNinety years ago brick manufacturing plants lined the Hudson River south of Albany. They thrived on clay deposits along the river, access to barge transportation, and proximity to booming construction markets, especially in New York City. By 1950 the number of brick plants was down to 10. Industry consolidation and modernization, lower demand in the Northeast, and brick companies' move to fresh sources of raw material in the southern United States contributed to the decline. Today there is one brick-making plant in the state: Powell & Minnock Brick Works Inc. in Coeymans, established in 1895. It has an annual output of about 50 million brick, and ships product as far north as Canada, south to Delaware and west to Ohio. (In the business, "brick" is used for both the singular and the plural of the word.) Powell & Minnock's four managers are now trying to buy the company from its Turkish owners to prevent it, too, from disappearing. Negotiations started a year ago. On Oct. 5, the owner, Isiklar Holding of Istanbul, shut down the Powell & Minnock plant and gave the managers until the end of the month to come up with a buyout offer. The managers are now working to raise between $2.3 million and $2.6 million for acquisition, capital improvements and an operating line of credit. Sixty employees have been laid off while they work on their plan. In the yard at the Coeymans plant are more than 7 million brick, sitting in cubes of 530, waiting to be shipped to customers. Inside the small one-story brick office building, however, the four managers are working full- time on a buyout plan. They have retained Donald Zee, an Albany attorney, to help put together the deal, and are working with Albany County Legislator Peter Clouse (R-Coeymans) to pursue state economic development incentives. Isiklar did not shut down the plant because it is unprofitable, said Charles Cockrell, one of the principals. The holding company is retrenching for strategic reasons, he said, because of the poor state of the economy in Turkey. Brick making in the United States no longer fits into company plans, Cockrell said.

P & M Ruins Powell & Minnock's efficiency has suffered in the seven years since Isiklar became owner, however, Cockrell said. Apart from new grinding equipment and a new machine for "extruding" brick purchased three years ago, Isiklar has made few modernizing investments. The last major investment was a new molded-brick plant, built in 1989. At the time, Powell & Minnock was owned by General Dynamics Corp., the diversified industrial giant known for its manufacture of tanks and submarines. Cockrell and his wife Roberta Cockrell, the chief financial officer, came to Powell & Minnock 2 1/2 years ago from another brick manufacturing company in Pennsylvania. The other two managers involved in the buyout plan are Jerome Leff, the regional manager, and Robert LaMora, the plant manager, who together have 59 years with Powell & Minnock. "Once you get brick dust in your blood, you can't get it out," said Leff, who started in the business 40 years ago and joined Powell & Minnock in 1971. Like cement manufacturing, brick making has always been important to the economy of southern Albany County. Clouse, the Albany County legislator from the area, said many of his relatives worked in the brick plants, including Powell & Minnock. The 60 union jobs at the plant have an important multiplier effect on the county's economy, Clouse said. Powell & Minnock makes extruded brick, where the soft clay comes out of a machine like toothpaste out of a tube, and is cut with wire into individual brick. The other kind is the more expensive molded brick, where each brick is molded separately for a more old-fashioned look. The company's brick is found in hundreds of local structures, from the 19th century brick-paved streets of Cohoes to Albany High School, built in the 1970s. Apart from the nostalgic reasons, the managers say there are sound business reasons why the Powell & Minnock plant should stay in business. It is an operating plant, with an established work force, a known product, and established client base, Leff said. Clients include the New York state Office of General Services. For the state prison system alone Powell & Minnock has supplied 20 million brick. Demand for brick is high, although it has softened somewhat in 2001 with the slowing economy. According to the Brick Industry Association, U.S. brick manufacturers produced and shipped 5 billion brick in the first seven months of this year, down from 5.4 billion in the same period in 2000. The industry is working at about 95 percent of capacity, according to the trade association. "I think it's a great business opportunity," said Leff, the regional manager. "We're an established, well-diversified business with a known product." Leff said it would be almost impossible to build a new brick plant from scratch because of the amount of land it requires to mine the raw material and the difficulty obtaining environmental permits. All of Powell & Minnock's permits are in place, he said. Gregg Borchelt, vice president of the Brick Industry Association in Reston, Va., said he knew of one company, Kansas Brick & Tile Inc. of Hoisington, Kan., where the managers bought the firm back from another corporation. Of the 44 brick manufacturers in the United States and Canada, 33 are closely held corporations, Borchelt said. Six are publicly held, and five are subsidiaries of larger corporations. If Powell & Minnock were not to reopen, Leff said, "It would be another lost industry to New York state." |

==========

Robert Lent

Coeymans, NY (1904-1920) |

Sutton & Suderly Brick Co.

Coeymans, NY (1885 - 1957) |

A Brief History of Coeymans

by William Wade, Master Engraver, 1846:

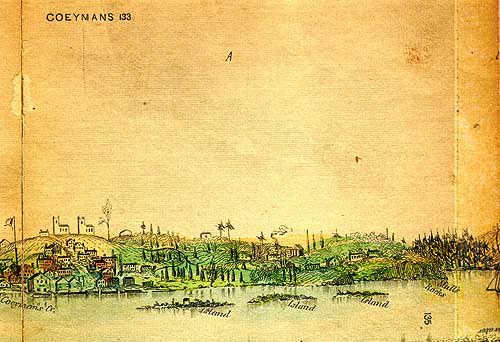

Coeyman's Creek on the left; Mull's Rock on the right

(engraving by William Wade)

From https://www.coeymans.org (edited):

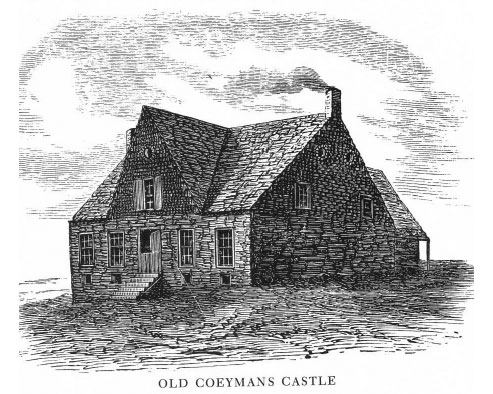

In the late 1670s, Barent Pietuisz Koigemans (the Dutch spelling for Coeymans), with the permission of the commissioners at Albany, purchased a large tract of land from the Katskill Indians. The land was approximately 120 square miles along the Hudson River, from Bethlehem to Coxsackie (including the modern towns of Coeymans, New Baltimore and Westerlo). Here Koigemans erected his home, known as the Coeymans Castle, two sawmills and two gristmills along Coeymans Creek. The Coeymans' mills were the catalyst that turned the mostly rural area into a flourishing commercial and industrial river port, making Coeymans well known to river travelers for hundreds of years.

(drawing from Ravena Coeymans Historical Society website).

By the mid 1700s, the British sought control over the area, resulting in the French and Indian War (1755 - 1763). By the end of the Seven Year War, the French surrendered to Great Britain, and for roughly fifteen years, colonists lived under royal British government control. However, in 1776, the Revolutionary War between the Americans and the British commenced and the ship building industry in Coeymans flourished, with the local sawmills supplying lumber for the construction of ships (gunboats or gundelos). An encampment of Colonial troops was also stationed in Coeymans.

Following the Revolutionary War, the Hudson River Valley area was rapidly settled. The Town of Coeymans was officially formed in 1791, and by this time it was already an established town with a prosperous riverport, Coeymans Landing. The Landing was an essential commercial and recreational port on the Hudson River, used for shipping building materials and local farm produce to the Port of Albany. Merchants' records reveal the shipping port traded spices, molasses, tobacco, cloth, clothing, rice, brandy and spirits.

In the late 1700s, there were many brick companies and mills along the Hannacroix Creek including Dean's Mill, Aquetuck (Peacock's Corners), Coeymans Hollow, Alcove (Stephensville), and Indian Fields (inundated in 1930 to make way for Albany's water supply, the Alcove Reservoir). Alcove was known for its mills and Mossy Hill Stone Quarry, which is still in operation today. Hydrologic power from the Onesquethaw Creek and the Hudson River supported the brickyards, quarrying sites, and grinding and lumber mills on the water.

By the 1800s, Coeymans Landing consisted of 30 houses, wharves and several sloops, a post office, two gristmills, and a sawmill. Many homes were built in Coeymans Landing between 1820 and 1850, a period of growth resulting from river sloops' positive impact on shipping and the close of the War of 1812. Homes on First, Second, Westerlo and Church Streets were built at this time in the Greek Revival, late-Federal and Gothic Revival styles. A number of Greek Revival style churches were built during this period for the Methodist and Dutch Reformed faiths.

By 1866, the Landing was a well established, thriving business center. Businesses included general merchandise, blue stone dealers, dry goods dealers, groceries, boots and shoes, hats and caps, paints and oils, two attorneys, the Coeymans Gazette office, two physicians and surgeon practices, forwarding and commissions, and a hotel. In 1865, Acton Civill, a wealthy land speculator and merchant in New York City, expanded his small Gothic Revival cottage for a summer home located at the intersection of Main Street, Church and Fifth Streets. The house remains one of the Landing's most prominent architectural landmarks.

From the late 1820s to the late 1890s the Hannacroix Creek provided waterpower for paper mills, two of which were located in the Town of Coeymans: the Ravine Mill, and the Valley Mill. The Ravine Mill was located in the hamlet of Coeymans approximately 100 yards west of NYS Route 144 near the Albany-Greene County border. Operational from 1832 to 1885, the mill was constructed specifically for manufacturing paper and used both water and steam to operate its equipment. The Valley Mill was located in the hamlet of Alcove at the junction of NYS Route 143 and County Route 111. Originally a cloth dressing and carding wool mill, it was converted to manufacture straw wrapping paper. The paper mill operated from around 1848 to 1892. In 1885, the mill reportedly had 25 employees and the ability to produce 3.5 tons of wrapping paper in one day. The paper was transported to Coeymans Landing and later shipped out to other Hudson River ports. A fire destroyed the mill in 1892, however the 110 foot tall chimney still stands.

The town was first connected by rail to the City of Albany in 1864. The Saratoga and Hudson Railroad only operated for a short period of time and was later called the "White Elephant Railroad." It left the town without a railroad until 1883 when the New York West Shore Buffalo Line was completed. With it, Coeymans Square, whose name was changed to Coeymans Junction, flourished. Coeymans Junction is now Ravena.

During winter months, the ice harvesting industry became a popular new business in Coeymans, with an ice storage house capable of holding 100 tons of river ice, which was mostly shipped to New York City by barge or steamboat. There were a few icehouses in Coeymans Landing and one on Barren Island. J.N. Briggs ran the largest ice operation. When modern refrigeration replaced the need for iceboxes, the icehouses were used to grow mushrooms.

In 1879, Briggs developed an amusement park called Baerena Park on Barren Island. The park included docks, a covered dance platform, a Ferris wheel, merry-go-round, refreshments and an Observation tower. A steamboat docked at Coeymans Landing was used to ferry people to the island on a regular schedule.

The Powell & Minnock brick company opened in the late 1880s, along with other brick companies such as Sutton & Suderley, Roah Hook, Hardwick & Walsh, Zeigler & Zeigler, Sutton & Sinsabaugh, and Adomos.

By the late 1890s, Coeymans began to change dramatically. The Coeymans family gristmills closed after 200 years of operation, and John Briggs purchased the rest of the Coeymans family land. Several fires destroyed numerous buildings in Coeymans Landing. In the early 1900s John N. Briggs started the Atlantic Light & Power Company, which provided power to Coeymans, Ravena and New Baltimore.

Through the 20th century, the principal industries shifted from the docks to the rail yards, and the riverfront, once the focus of life within the hamlet of Coeymans, slowly began to decline. By the early 20th century, the railroad virtually replaced the river as the way of transporting goods, and a new community began to blossom in and around the new transportation center (Ravena).

As the riverfront docks were abandoned, commerce in the Hamlet slowed, much of the long time residents began to slowly migrate away from the riverfront. Many of the existing shops were torn down, left vacant to later burn down, or converted into residential units. A large population of migrant farm workers who worked for the mushroom growing and processing facility were housed in the Hamlet. After the mushroom facility closed, many of these homes were again abandoned and left to deteriorate.

At this time, the City of Albany was flourishing and after long getting their drinking water from the Hudson River, the city leaders began searching for a purer water source. After researching other water sources, the City found the Hannacroix Creek in Coeymans to be the purest and the creek was dammed, flooding 1,440 acres and creating a reservoir with a capacity of 12 billion gallons. The existing settlement, known as Indian Fields, was re-located to create the Alcove Reservoir. The late John Boyd Thatcher turned the lever that closed the gates of the dam in 1929, and the municipal water system was turned on in 1933.

The limestone escarpment of the Helderberg Mountains brought the cement industry to Coeymans in the early 1960s. Limestone of the Manlius and Coeymans formations are the lowest of the limestone formations and are the main units being mined for cement raw materials. The Atlantic Cement Company was established in 1962, and was later taken over by Blue Circle Cement in the mid-1980s. Lafarge North America acquired Blue Circle in 2001 and today owns approximately 3,400 acres of land in the town including the plant. Lafarge is the largest cement producer in the world, and the Ravena/Coeymans plant has the capacity to produce two million tons of cement annually. A large area of the Town is owned by Callanan Industries Inc., which quarries the limestone beds for construction materials. These industries are the top employers in Coeymans.

Over the past few decades, Coeymans has been experiencing slow but steady commercial and residential growth. The majority of the Town's western area remains mostly open and undeveloped with the land either in agricultural production or grown over to secondary forest. A large area surrounding the Alcove Reservoir (approximately 4,000 acres) is owned and controlled by the Albany County Water Board. Many Coeymans residents enjoy a rural lifestyle, while commuting to work in the Albany area or other nearby regions. In the early 1990s, the Town began to focus its attention on waterfront revitalization, and since then a number of improvements have provided recreational boaters with a reason to visit the Hamlet.

Today, industrial properties are almost all contained within the eastern portion of the Town between the Hudson River and Feura Bush Road (County Route 102). The majority of Industrial property is owned by Lafarge Sand and Gravel, Blue Circle (Atlantic Cement), Callanan Quarries, Powell- Minnick Brickworks, and New York Quarries. A large area is located just north of the hamlet between NYS Route 144 and the Hudson River. Once a brickyard owned by Powell-Minnock Brick Works, this land is currently for sale.

Webmaster Note: The brickyard area is now the Port of Coeymans Marine Terminal a privately-owned, full service marine terminal and port.

==========

SOURCES CONSULTED:

deNoyelles, Daniel, Within These Gates

Hutton, George V.,The Great Hudson River Brick Industry

https://www.hudsonvalleyruins.org

https://www.nyserda.org/Press_Releases/press2000.asp

https://www.coeymanshistory.org/

https://www.coeymans.org/history.htm

https://www.coeymans.org/Comp Plan/Coeymans Comp Plan Draft05-24-06.pdf

https://www.hhr.highlands.com/default.html

https://www.portofcoeymans.com

https://maps.google.com

Hudson River Brickmaking | Brick History/How Bricks Were Made Links | Contact Form | IBCA | BOOK SHOP Visitors' Comments/Collections/Brix Pix | Our Collection | HOME |

a service of FYI World Media. © 2011 D. Bayley