|

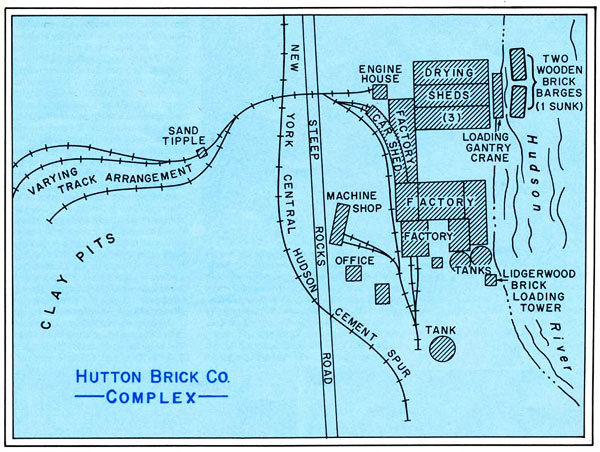

Hutton Brick Company

Kingston, NY

HUTTON brick fragments on Kingston Point Beach

(Photos by D. S. Bayley)

The HUTTON Brickyard:

A major manufacturer of quality brick (primarily for NY City) from ca.1870 to 1980

In 1865 William Hutton and John H. Cordts purchased land in the Rondout area of Kingston along the Hudson River. The northern portion of the property included a prominent landmark called Steep Rocks. These were bare-faced cliffs above which were woodlots, perfect for supplying fuel for a brickyard.

On the adjacent property to the north, David Terry had already been making bricks for fifteen years. The rapidly growing New York City brick market plus the prospect of enormous clay resources made this property very attractive.

William Hutton was virtually an absentee owner, a lumber company a mile away was his primary enterprise.

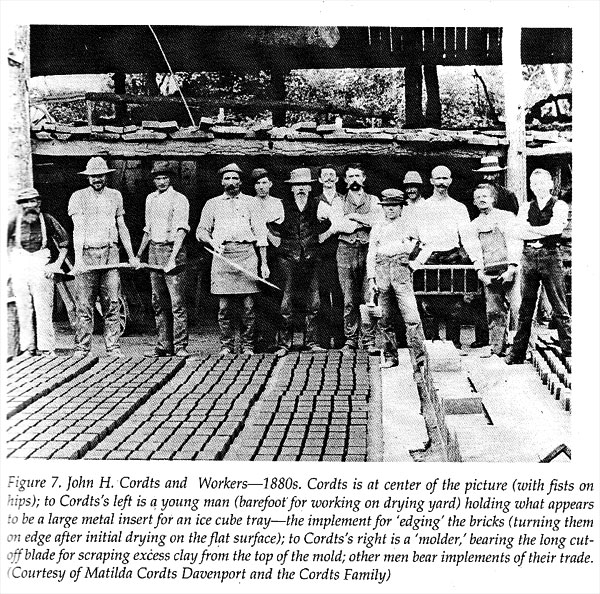

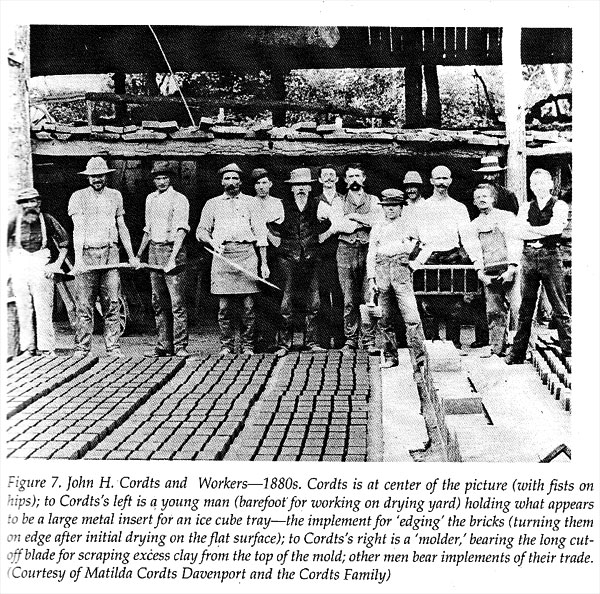

It was John H. Cordts who actively ran the company for twenty-five years.

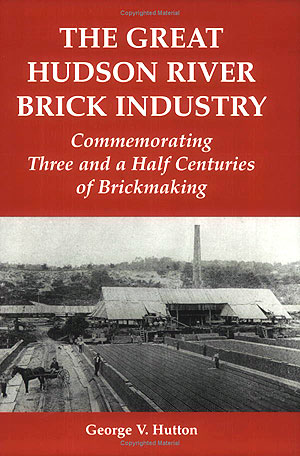

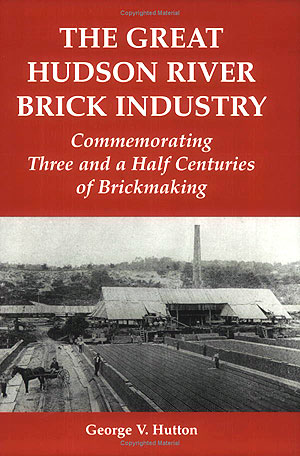

In The Great Hudson River Brick Industry George V. Hutton wrote:

"The U.S. Census of 1870 shows the Cordts and Hutton yard off to a fast start, making ten and one half million bricks with six steam-powered brick machines, thereby making this one of the largest-volume manufacturers on the river."

In 1873 Cordts built his own mansion--Edgewood Terrace--on a hill above and to the south of the brickyard. A real estate listing described its glory: "Majestically sited on 13 acres above a broad bend in the Hudson River, Cordts Mansion

John Cordts retired in 1887 and died in 1891. From 1890 until 1965 the business was known at The Hutton Company.

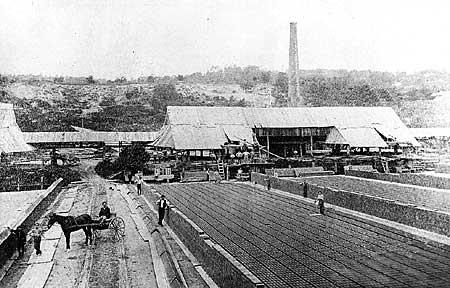

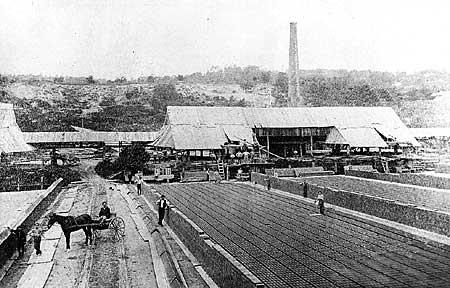

The Hutton Company ca.1900.

The brick machine building is at the rear of the drying yard,

with radial spokes of tempering wheels visible at each end.

(Courtesy of Hudson River Brick by Brick Manufacturers Association of New York)

William Hutton became sole owner and president until his death in 1897. The business was then incorporated and run by six family stockholders. Son, George, was the company's treasurer and secretary until he died in 1920. His younger brother, Robert Kerr Hutton, became president. In 1965 the company was sold to the Jova Mfg. Co. They sold it to Terry Staples in 1970 and it closed in 1980.

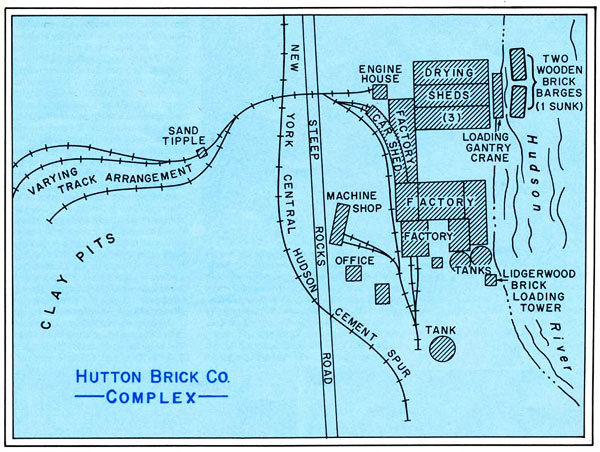

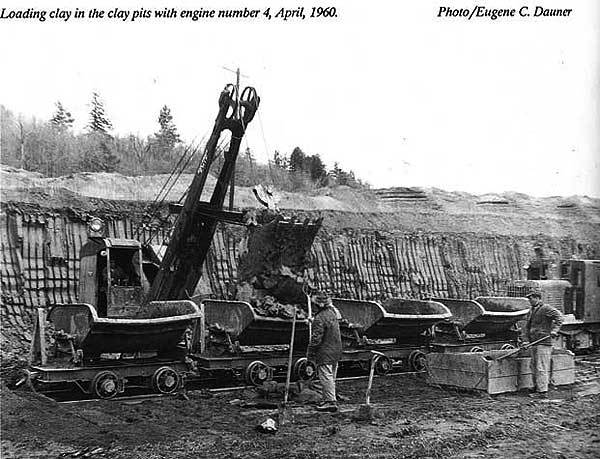

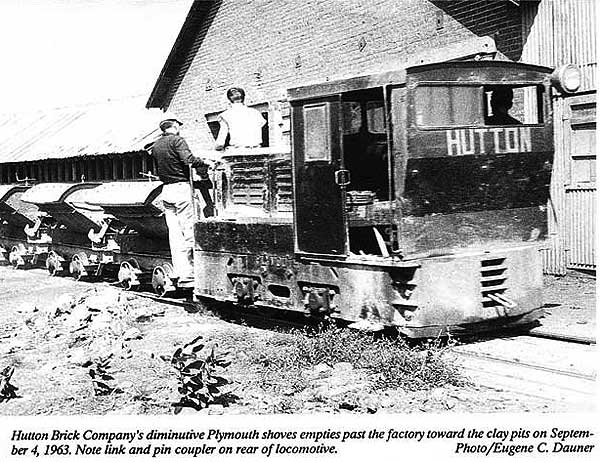

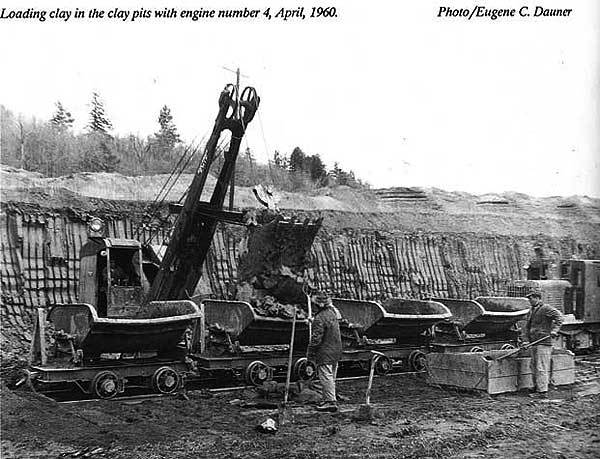

(Reproduced with permission from the June 1989 edition of Railpace Newsmagazine)

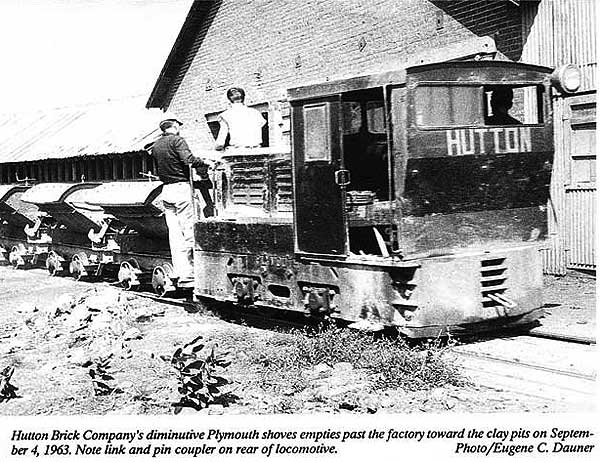

(Photo reproduced with permission from the June 1989 edition of Railpace Newsmagazine)

(Photo reproduced with permission from the June 1989 edition of Railpace Newsmagazine)

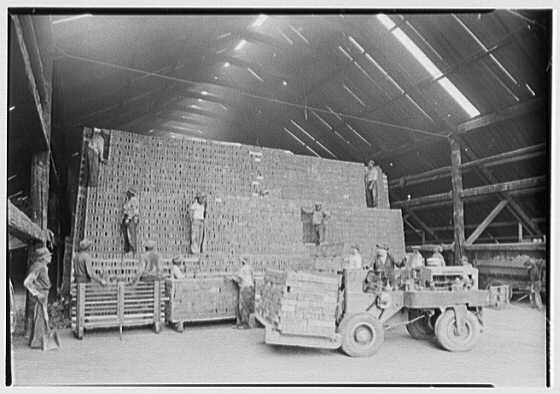

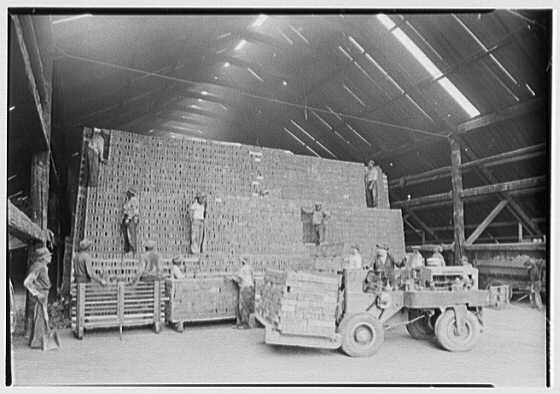

Hutton Brick Works, Kingston, New York, 1939.

Taking bricks from kiln.

(Gottscho-Schleisner Collection - Library of Congress)

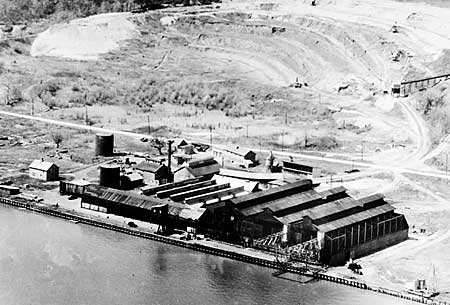

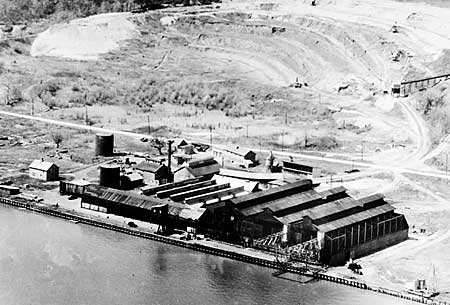

The Hutton Company, 1948. The completed modernization program, including the steel kiln sheds,

erected in 1940 (lower right), with gantry at right-hand kiln bay.

(Photo by Air Photos Associates Inc.)

Hutton Brickyard, Aerial View

(From the Terry Staples Collection and courtesy of the Hudson River Maritime Museum)

Posted on Facebook:

John Thompson

I worked in the Brickyard one summer back in the 50's. I want to tell you, it was hard dirty work. I remember they put me in the "drying kilns", where wet brick came in on metal plates - about 100 lbs each

- via wire conveyors. They had to be lifted off the conveyor and put into pipe-racks to dry. The drying houses where you worked were

slowly being heated up, so it was not only tough grinding work, but hot as h--- too. The slabs of brick came so fast, I couldn't keep

with the other huge strapping guys working beside me, so I caused a big mess of wet clay all over the place, and, regrettably lasted less than a day, before being transferred to an little easier job. You started work real early, but were finished be mid-afternoon, when everyone just went and jumped in the river. I was covered with red dust, which was used to color the bricks, and caked on with sweat - - so I was forced to take everything off on the back porch, and after taking a bath, the bath water looked like red beet juice. Rough and dirty work, but great $$$.

Dec 17, 2011

Rich Turck

If you'd been at Hutton's yard they had a shower room right next to the boilers - endless hot water and everyone that used them went home clean and in their street clothes. But the work was hard, no question about it.

Joe Amato

My father was the president of the brickhandlers union for the entire hudson valley brick workers in the 50's and 60's...Just a side note...I worked at the Hutton brick yard 1 summer...Tough work..@Rich..you are right..any one getting hurt just made due with whatever was available..Rags..Clay.etc..

Joe Amato

@Rich...by the way your father was our yard supervisor when I was there..Good Man...

Joe Amato

I took a shower there every day, but before that i would dive into the river from the dock, then take a shower..Jim Maccaline Jr. and i would do this every day after work..The old guys would watch us and wonder if we were crazy...

Rich Turck

Thanks for the comment re: my dad, Joe. He was very young when he was selected to be plant superintendent. But everyone knew that he knew the plant inside-out. From the clay banks to the dock, nothing happened on that yard that he didn't understand. Tough boss and father, but consistent in both roles.

Dec 18, 2011

Hutton Company Ruins, Satellite View

For an Interactive Google Earth © page, CLICK HERE

This brickyard was used by the following companies:

Cordts & Hutton, Hutton, Jova Mfg. Co (JMC), and Staples Co.

A VISION FOR THE FUTURE...

(video source: thehuttonbrickyards Facebook page)

--------------------

From the final chapter, Chapter 7:

EPILOGUE FOR A DEPARTED INDUSTRY

"The Hudson River brick industry went down before an array of

overwhelming forces, including large demographic changes, competition by

new technologies, and by brickmakers in distant locations that had

achieved access to the New York market, as well as new environmental

standards. During its lifetime, nothing can gainsay that industry’s

indispensable contribution to the very existence of New York City, where

the record of that accomplishment is everywhere to be seen. With the

exception of IBM, there is nothing comparable to that industry in the

Hudson Valley today in terms of size and consequence of its production.

....

Soon enough, virtually all vestiges of the physical presence of all that

intensive manufacturing activity will have observably disappeared. The

great majority of the substantial changes to the landscape, resulting

from the excavation operations, will not be discernible due to

overgrowth, a condition that is nearing completion at this writing.

Development of brickmaking sites for other purposes will also obliterate

all signs of past endeavors.

Perhaps one of the two graceful

nineteenth-century brick boiler flues at East Kingston (the Shultz

yard flue being a personal favorite), built to power the steam engines

that drove the brick machines, will be treasured as the sole remaining

industrial artifact of three and one half centuries of the existence of

the great Hudson River brick industry."

--------------------

At the beginning of the twentieth century, brick manufacturing was the dominant industry on the Hudson River. One hundred thirty manufacturers employed seven to eight thousand workers. It was the largest brickmaking region in the world, supplying vast amounts of this most essential building material to the fastest-growing city in the world. Spanning three and a half centuries, this industry ceased to exist in the year 2002. Included here are accounts of technological innovations, manufacturing methods, periods of enormous production, and wrenching business crises that transformed the entire industry. Elements of this history include the arrival of immigrants from Ireland, Italy, Hungary and the American South, as well as labor relations.

--------------------

George V. Hutton, a graduate of Williams College and Yale School of

Architecture, was a retired architect with firsthand experience in

brickmaking at the Hutton Company in Kingston, New York. His book is now back in print! Click here to order your copy.

--------------------

Hutton Company Ruins, July, 2006

as seen from Kingston Point Beach

Hutton Company Ruins, July, 2006

Hutton Bricks on Kingston Point Beach, July, 2006

(Photos Copyright © D.S. Bayley)

SOURCES CONSULTED:

Beers, F. W., 1891 map

deNoyelles, Daniel Within These Gates

Gill, Kathryn, "Completed in 1874, Kingston’s Cordts Mansion has Rich History." Daily Freeman (Kingston, NY)

DiMauro, Gary, Real Estate

Hutton, George V., The Great Hudson River Brick

Industry

New York State Geological Survey, 1889

NY Times Archives

Rieck, Fred

Sanborn Map, 1899

Schupp, Edward M., Kingston Tour

Sullivan, James,

History of New York State, 1523-1927, [Vol. 6]

1873-1931.

Van derPoel, Andy

Hudson River

Brickmaking | Brick

History/How Bricks Were Made

Links | Contact Form |

IBCA

Visitors'

Comments/Collections/Brix Pix | Our

Collection

HOME

Search BrickCollecting.com:

To search This Page, Hit

CTRL-F

|

|

|