|

HUDSON RIVER & NEW ENGLAND

A collection of Hudson River & New England Brick with a brief history of the yards and towns where they were made.

|

Search This Site For Brick Info: |

To search the page you are on, Hit CTRL-F |

Aldridge Brick Company

Thomas Aldridge Dutchess Junction, NY (1899, 1905) 10 machines (found at the brickyard site)

From Fred Rieck:

"The "A.E.A." brickmark "ties" into Aaron E. Aldridge, a brick manufacturer located in Dutchess Junction. A.E.A. is listed in city directories as early as 1887.

I can't tell you just when the A.E.A. marked brick actually came into production.

A later, 1896 directory entry lists Aaron as being affiliated with Aldridge Brothers

(a/k/a Aldridge Brothers & Company), also brick manufacturers - the brother likely being George L. Aldridge.

Aldridge Bros. Co. is listed as early as 1890

Bricks marked A.B.C (the letter C having a unique segmented form), have been found comingled with ALDRIDGE scrap. There are several manufacturers that marked their brick with "A B C" making it difficult to ID them with out seeing the them." ========== "Daniel Aldridge resided in Mudhole, NY (which is now known as Roseton, NY). Daniel is thought to have moved to Newburgh, NY, sometime between 1810 and 1817, due to the fact that his wife was from there. One of his sons was Thomas Aldridge born in 1818 and died August, 1892. Thomas bought a farm near Fishkill Landing, NY in the fall of 1853 which later became the 'ABC' (Aldridge Brothers & Company) Brickyard in Dutchess Junction, NY." (SOURCE: Steven Blair Aldridge Family Home Page) Thomas' son Aaron Ennis Aldridge was born on January 19, 1851 in Balmville, near Newburgh, NY. He worked with his father at the Dutchess Junction brickyard and when his father moved to Chelsea, Aaron took over. He became one of the leading figures in the brick industry, was president of the Thomas Aldridge Brick and Land Company and also served as vice-president of the Greater New York Brick Company. He was prominent as a manufacturer and still more so as a selling agent in New York City where he had offices in the Times Square Building. From there he handled the output of many yards along the river. He was recognized throughout the country as an authority on brick making and the brick market. He died in 1925 in Beacon, NY. (SOURCE: Sullivan, James, History of New York State, 1523-1927, [Vol. 6] 1873-1931.) ==========

From Sloops of The Hudson,

by: William E. Verplanck and Moses W. Collyer,

G.P. Putnam's Sons, New York & London, 1908:

========== ALDRIDGE bricks have been found at the Castle on Bannerman's Island. We found some great photos here, here and here. ==========

For Our New DUTCHESS JUNCTION Page:

|

|

From Fred Rieck: In a 1929 Poughkeepsie city directory,

George H. Terwilliger is listed as Sup't. and Otis A. Allen as Treasurer of the newly formed

Poughkeepsie Brick Corp (PB CORP), located on Van Wagner Road nr. NYNH & HRR in Arlington. Poughkeepsie Brick Corp. is about the last yard to operate on "Brickyard Hill." The directory lists the principals as Walter J. Travis (pres); W.N. Wetterau (V. P.) and John B.Vanderwater (Sec'y). J.B. Vandewater is also listed as an "Attorney-at-Law,"

More information on

|

Brewster J. Allison & Co.

Grassy Point, (Haverstraw) NY (1876) 6 machines (found in Haverstraw Bay by Amanda Bayley)

In 1883, Brewster J. Allison owned a brickyard in Haverstraw and produced 9,000,000 brick with 6 machines,

employing 80 men. He leased the land from George S. Allison.(History of Rockland County, J.B. Beers & Co., 1884)

On Jan 17, 1903 a brick census (inventory) was taken and Brewster J. Allison & Co. had 65 Arches with 2,800,000 brick on hand. (Rockland County Messenger, Jan 22, 1903) ========== From The History of New York State, Lewis Historical Publishing Company, Inc., 1927, Biographies, Part 6: Brewster J. Allison was born July 5, 1821. He attended the Stony Point District School and the Peekskill Military Academy, where he took up the study of surveying. After graduating from Peekskill Academy, for the first few years he engaged solely in engineering, but later became interested in farming and the manufacture of brick, and owned extensive property interests in the town of Stony Point. There were no incorporated villages in the town, but there were, however, several centers of population, called variously villages, "corners" or hamlets. Largest of these was Stony Point, which lies close to the southern boundary of the town. The large Allison homestead, built in 1821, is now occupied by Mr. Allison's son, Ralph D. Allison. Perhaps the oldest house in this village, known for many decades as the Alexander Waldron place, is owned and occupied by Mr. Allison's daughter, Mrs. Frances Bontecou. The construction of this home antedates the Revolution, and the house, like the town, figured in the history of that war. About 1850, twenty years before the place then known as Florus Falls became the village of Stony Point, one Theodore Smith caused his farm to be surveyed in village lots and blocks, and called it the village of Brewsterville, after his wife's family name. So is the name Brewster perpetuated; and the name Tomkins, likewise, in Tomkins Cove.

Brewster J. Allison was one of the outstanding men of his time in county and town. He held many town offices, served on State committees on roads and bridges and towns and villages, was a member of the town school board, town superintendent of schools from 1848 to 1853, and was member of the Legislature, in 1850. Brewster J. Allison was a communicant of the Presbyterian Church, and for a long period as elder. He was a generous, talented, friendly man, beloved of his associates in business and society; and his loss was widely and sincerely regretted.

|

American Brick Co.

Origin unsure: There was an American Brick Co. incorporated in Manhattan, NY in 1920. We found a stock certificate dated 1928 for American Brick Co. in Massachusetts. In "Brick Manufacturers of the United States" Jim Graves lists an American Brick Co. in Croton Point, NY (no dates given) and in Scranton, PA from 1923 to 1922.

(found by Jason in The Bronx, NY)

|

Anchor Brick Co.

Croton Landing, NY (1888 - 1895) The "anchor" logo design was registered by Schuyler Hamilton.

(Thanks to Michael Anzalone for the first photo.)

|

Arrow Brick Co.

Danskammer Point, NY

In 1905 this brickyard was operated by David Maitland Armstrong. In its first year, it produced 5 million brick.

==========

In conjunction with our sister-site HudsonRiverHistory.com we have completed a new webpage:

A BRIEF HISTORY of ROSETON and DANSKAMMER POINT, NY

Here you will find a compilation of our research on the brickyards in this area (ROSE, JOVA and ARROW).

|

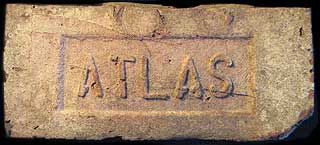

Atlas Brick Co.

Hudson, NY (1905) (found at the brickyard site)

September 4, 1910, Sunday

HUDSON, N.Y., Sept 3. -- Springing out of the woods which border the private road leading into the Atlas Brick Company's works, two miles south of Hudson, masked highwaymen to-day shot and mortally wounded Denton Fowler, 3d, killed George Ragsdale, the driver of the buggy in which Fowler was riding, and escaped with a satchel containing $5,000, intended for paying off the employes of the works.

To read the full article, Click Here. ========== From the 1910-1911 Obituary Record of Graduates of Yale University: "DENTON FOWLER, son of Everett Fowler, a brick manufacturer and bank president of Haverstraw, N Y , was born in that place July 28, 1885. His mother was Anna (Dennison) Fowler. He was prepared for college in the Lawrenceville (N J ) Schools. He was a member of the class of 1908 during Freshman year, but joined 1909 at the beginning of Sophomore year. He was a member of the University Glee Club, and of the Class Day committee at graduation. After finishing his college course he entered the employ of the Atlas Brick Co, of Hudson, N Y, of which his father was an officer, and later was appointed paymaster. As he was driving through the woods two miles south of Hudson, carrying a large sum of money to pay the employees of the company, Mr Fowler was attacked and shot by five highwaymen, others acting as signal men, and died two hours later at the Hudson Hospital, September 3,. 1910. He was 25 years of age and unmarried. He was a member of the Central Presbyterian Church of Haverstraw."

|

Brophy & Brother

|

Bartlett Brick Co.

Bartlett Bros.

Hudson, NY found at the brickyard site (along with ATLAS and *DK*)

Fred Rieck writes:

The Bartlett Brothers are Fred W. Bartlett and George C. Bartlett. ... listed in the Hudson City Directory from 1897 to about 1909. Atlas Brick Co. debuted in 1910. Bartlett Bros. is no longer listed that year (1910). During their tenure, B B had two varieties of B B (the second being B B with serif letters). They also made a reverse lettered BARTLETT and a "correctly" written BARTLETT. I have only seen two of the reverse lettered ones.

|

BelleIsle Brick Works

|

Edward D. Bellefuille

George's Island, (Montrose) NY (this was a hard one to ID - - thanks to Fred Rieck for this one!)

|

Berlin Brick Company

Berlin, CT (found in Newtown, CT by Nancy Nouss-Brown)

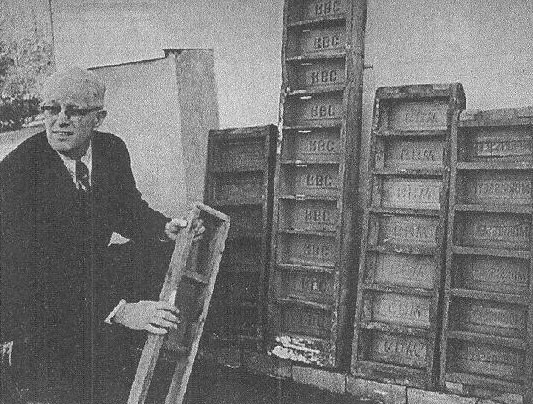

From a museum brochure: "The museum houses a brick display with bricks, brick molds, signs and terra cotta pieces from Berlin’s many brick manufacturers. Berlin was prominent in the brick market even as late as the 1960’s."

In 1842, Cornelius P. Dunham established the first brickyard in Berlin, CT. Because the clay in Berlin was so perfect for brick making, the business continued for a little over 120 years. Berlin was known throughout the northeast for brick making. The salary for an average worker was 1-2 dollars every 10 hours. Over 90,000 bricks were produced each day with as many as 90 men and women working together. In 1910, Berlin had about 11 brickyards, and yearly produced about 102,500,000 bricks. The Great Depression ended the building construction. The last brickyard to close was a flower pot company which didn't last too long. The electric shovel arm is still visible in an old clay pit on Route 72. The hole was bought by John Carbo who had a company on Christian Lane. John Carbo didn't make enough money for electricity for the electric shovel so it was never used and abandoned. Clay has made a long way in the town of Berlin, but it had to end sometime, but overall it was very successful.

Source:

Other brickyards that were in Berlin, CT include: |

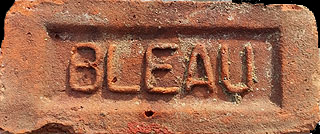

Joe Bleau

Mechanicville, NY

I was born in the Eastern Township of St. Christine, Quebec on September 8, 1908. I grew up on a farm with

cows, horses, pigs, chickens and a few ducks and went to school in a one-room schoolhouse until the fifth

grade. On August 26, 1926, I left from Windsor Station in Montreal to come to the United States. I took the

milk train at 10:30AM and arrived in Troy at 5:30PM. I could speak no English. My brother, who was living in

Watervliet, met me at the station. My uncle owned the Bleau Brick Co. in Watervliet and I started working

there on Monday. My first job was to feed the horses and drive them to bring clay to the granulator. Because

this brickyard had what was known as an “open yard”, it operated only in the late spring, summer, and early

autumn. When the brickyard shut down for the winter, I went to work on Riberdy’s farm in Waterford. I

milked cows, cleaned the barn, put corn in the silo, plowed land for the following spring, and chopped wood

up on Shaker Road.

I was back at the brickyard in the spring of 1927 driving horses to and from the granulator, earning $24 a week. That was “big money” then because I was making nothing back in Canada. I learned how to operate both a gas-powered shovel and a steam shovel. When the brickyard closed for the winter, my cousin offered me a job. I went to Berlin (east of Troy) and hauled logs out of the woods for $1 a cord. Sometime the snow was up to my butt, but I was young! After hauling the logs to the road, they were picked up by a truck and taken to the brickyard in Watervliet. Back then, wood was used to burn the kiln to fire the brick. In the spring of 1928, I was put to work as a “mold pusher”. A machine pushed through 19 molds a minute. Each mold contained 6 raw bricks and in a 7 hour shift, we made 43,000 bricks. The green bricks were put on drying racks before being fired. I hated this job, so I left the brickyard and went back to Canada for a visit. When I returned, I went to work at what was know as the “poor house” (National Automotive Fibers) in Waterford; we tore apart old mattresses to make some type of insulation for automobiles. I worked there one winter and got laid off. In order to survive, a friend and I went to Massachusetts and found jobs in a lumber camp, chopping wood to make railroad ties. By now, it was the Depression, so I spent the next few years doing some work at the brickyard and chopping wood in the winter. I got married in 1934 and that first winter was very difficult. I was chopping wood in Cohoes, but that didn’t bring in very much. My wife was earning $3 a week taking care of an elderly woman. By 1935, we were living on Main St. in Cohoes. I received word that my cousin wanted me back at the brickyard. I didn’t have the money to take the trolley so for my first week I walked to and from Watervliet until I got paid. I then took the trolley until I had enough money to pay for the registration on my light blue 1933 Willys. I had saved a $20 bill all winter long in case one of us got sick. I still had the $20 bill. Now I was operating the steam shovel, which I liked very much. There was a medallion inside the cab as proof that I had passed the “steam test”. Unfortunately, I fell off the shovel and spent the rest of the summer in the hospital. In the fall, we moved to N. Erie Street. We were expecting our first child. In the spring of 1936, Mr. Bleau asked me to come back to the brickyard and drive the BIG TRUCK! I was so thankful to have a full-time job. I delivered brick everywhere – Schenectady, Gloversville, Amsterdam, North Adams, Lenox, Lee. Jack Gaudette and Billy Nadeau drove the smaller trucks for local deliveries. Later, Mr. Bleau brought the former Troy Brick in North Troy on Oil Mill Hill. That brickyard could operate all year long. During World War II, I worked night and day, some weeks 100 hours due to the manpower shortage. Most of the men who worked in the brickyard had been drafted: Billy Nadeau, Jack, Joe, Franklin Gaudette, Mickey, Guy, Oscar Gilbert, Richard, Wilfred and Lawrence Bleau. The only ones left were Gene and Joe St. Pierre and a few men from Mechanicville. Bleau Brick could not make brick fast enough to meet the demand so we bought from a supplier in East Kingston. I would leave my home at 5AM to get to East Kingston. There, a crane operator would load the truck with 7,000 bricks. Then I drove to the Schenectady GE, dropped off that load and, by noon, was back in East Kingston for a second load. When I wasn’t hauling brick to Schenectady, I was making trips to Pittsfield or Gloversville. Travel was on Routes 9, 7, or 20, the main roads of the day. After my regular workday, I would spend a few hours repairing machinery. I would get home about 4PM, eat supper, rest and go back at 6PM to tend the kiln with Joe Leclair. At midnight, Joe St. Pierre and Joe Ten Eyck took over tending the kiln, which burned 24 hours a day for 5 to 6 days. Some Sundays I went to 6AM Mass, then to the brickyard and loaded a railroad boxcar. By noon, the boxcar was loaded with 32,000 bricks. The load had to be spread the length of the boxcar, the weight balanced evenly over the wheels of the car so it wouldn’t sag in the middle. I would toss 6 bricks at a time to Joe St.Pierre, who would then toss them to a man with a wheelbarrow who would unload his bricks into the boxcar. An unfired brick weighs 8 pounds but after being fired it weighs 6 pounds. So when I was tossing bricks, I was handling 36 pounds each time. I had muscles back then! When the veterans returned from service, we could make 43,000 bricks a day. I worked for Bleau Brick for almost 26 years. In 1952, I bought my own truck and became a tractor-trailer driver between Boston and Chicago.

(SOURCE:

https://www.spindlecity.net) |

Brigham Brick Co.

Henry R. Brigham East Kingston, NY (1922 - 1957) (9 machines in 1910) (found in Riverdale, NY and at the brickyard site)

Brigham Brothers Henry R. and William H. East Kingston, NY (1888 - 1910)

For our special BRIGHAM Page with a brief history and pix of the site Click Here |

Brockway Brick Co.

Brockway (Fishkill Landing), NY (1899) (Fishkill Landing was a village in the Town of Fishkill until 1914 when it was incorporated into the City of Beacon.)

In 1883, Edwin Brockway owned a brickyard in Haverstraw and produced 5,500,000 brick with 3 machines,

employing 50 men. He leased the land from Washburn, Worall & Palmer.(History of Rockland County, J.B. Beers & Co., 1884)

========== A note from Shirley Burris: "The Brockway Brick Company was founded by Edwin Brockway, my great, great grandfather, who bought the property and moved his family from Haverstraw. Following his death, his children, Charles LaRue Brockway, Frank, Fannie and I think there was another, inherited the property. My Grandmother, Esther Lydia Brockway Lewis and her siblings were born in the "big house" on the property."

For a great web page on the Brockway Brick Yard, Click here.

|

Patrick Brophy

from the Andy Van Der Poel Collection Grassy Point (Haverstraw), NY (1888 - 1903)  Photo courtesy Haverstraw Brick Museum |

W.D. Budd Brick Co.

|

Cary Brick Company

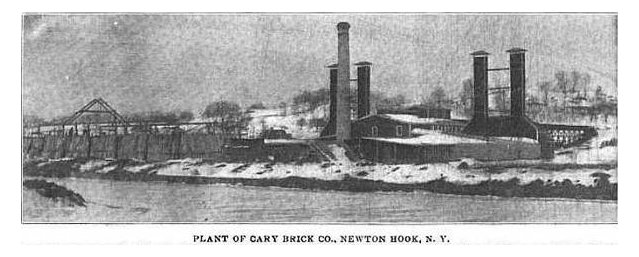

In "Brick Brands of the United States" Jim Graves lists The Cary Brick Co. with yards in Newtown Hook, Cohoes and Albany, NY. He states that the CARY brick with the CBMA symbol (as pictured above) came from the Albany yard. (CBMA= "Common Brick Manufacturers Association.") ========== Article on the CARY Brickyard at Newton Hook ==========

A Modern Brick Plant on the Hudson.(From The Brick and Clay Record,Vol. XVIII, JANUARY 1, 1903)With the assistance of Dame Nature keen enterprise and 20th century appliances have contributed toward making the plant of the Cary Brick Co. at Newton Hook, N. Y., ideal in every respect. This newcomer in the brick colony is conceded to be one of the finest brickmaking establishments on the picturesque Hudson, famed as the head-center of the industry in this quarter of the globe. All that goes to make a location desirable is found at Newton Hook in great liberality--pure sand in illimitable quantity, hills of clay that literally can never be exhausted and a small mountain of the best shale that the state of New York can boast. In addition to these admirable resources are the unequalled means of transportation afforded by the New York Central railroad on the one hand and the waterway of the world on the other. Of equal importance with location are the up-to-date labor-saving devices that have been incorporated in the new plant. Newton Hook was formerly Coxsackie Station, but the name was changed recently, partly because it was too frequently confused with the town of Coxsackie on the west shore of the river, and partly because the topography makes it appropriate, for a hook-shaped peninsula juts into the river at that point. The Cary property is several hundred feet south of the railroad station at one of the most commanding points of the eastern shore. Back of the buildings that comprise the plant rise a series of hills, each a mine of wealth from the viewpoint of the brickmaker, and the company owns 264 acres of these convolutions extending back from the river. The present buildings comprise two driers, each 53 x 160 ft., and a connecting structure, 50 x 80 ft., that houses the machinery, boilers and engine. From the midst of the group the stack rises to a height of 90 ft. This has a 4-ft. flue. The buildings lie between the railroad and the river, and, the shore being very marshy, it was necessary to fill in for quite a distance. The top layer of the sand hill was used for the purpose. To further insure solidarity, piles were driven for the foundations to rest upon. An 800-ft. sea wall was constructed, affording commodious wharfage, and the dock facilities were increased by dredging, giving a water depth of at least 10 ft. Work is well under way upon a kiln shed that will extend the entire length of the water front. Not only do the tracks of the New York Central pass the property, but the railroad is building two spurs to intersect it front and rear. When all is done the Cary company will have unexcelled facilities for shipping its product to every point, by river, canal and rail.

View from river showing sand, shale and clay clay banks in rear with the dock kilns,

|

Champlain Brick Company

Mechanicville, NY

Found along with LENOX in the remains of the Boyce Thompson Institute,

Dr. Paul Loatman, Jr., City Historian of Mechanicville, NY wrote:

From The Mechanicville and Stillwater Directory, 1911: |

Christie & McCabe

Haverstraw, NY (1883 - 1889) In 1883, Christie & McCabe owned a brickyard in Haverstraw and produced 8,000,000 brick with 4 machines, employing 50 men. They leased the land from Daniel De Noyelles & Co.(History of Rockland County, J.B. Beers & Co., 1884) |

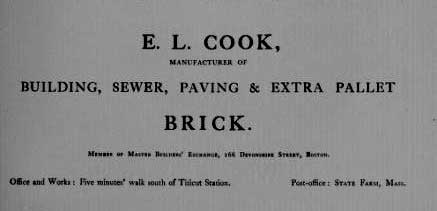

E. L. COOK

found in Cataumet (Cape Cod), MA by Tom Kingman, Pocasset MA

Tom writes:

The Cook brick was found in October, 2008 in the demolition pile of a chimney of an old seasonal home built between 1878 and 1932. Both W. Barnstable and Cook brick were used in the chimney with fireplaces on both first and second floors. The second floor bricks were W. Barnstable brick and joined with a fine red cement while the first floor brick were Cook brick joined with a white cement. Both cements were exceptionally weak and just turned to powder. The majority of white cemented brick were not embossed or stamped with the Cook name. A good guess would be that there was one Cook embossed brick for every 100 non-embossed white cemented bricks. This is about the same frequency as embossed to non-embossed W. Barnstable red-cemented ones.

==========

From a listing of brick mfgr's for MA: ========== A Brief History of Brickmaking in Bridgewater, MA:

First settled in 1630 as an outgrowth of the Plimoth and Duxbury plantation, the Town of East Bridgewater was an early industrial inland town located on the northern portion of the Taunton River system. Its early economy was based on agriculture but the community did have both grist and sawmills, iron forges and tanneries. The late 19th and early 20th century saw residential development along the trolley lines in the community.The Loucraft brickyard covered the area known in the 1600’s as the Devil’s Hop Yard, where early settlers had their homes. Joseph and his son razed about 10-12 feet of the area to extract clay for bricks. And they ran a boarding house, too, for lots of their Canadian labourers." ==========

Bridgewater Brickyard Burned ========== Brick production was Bridgewater's most prominent industry, and still is to this day. Established in 1886 and now with over 100 years of experience, the Stiles and Hart Brick Company remains the only brick manufacturer in Massachusetts. The Stiles and Hart Conservation Area has the remains of the original brick factory as well as many piles of bricks scattered throughout the property. This 75-acre site was an agricultural fairground with a grand exhibition hall from c1820- 1875. In 1895, a local teacher, Mr. William Basset, Sr., purchased the land and founded the Bridgewater Brick Company. The company mined clay and produced bricks on the site. In 1913, Stiles & Hart Brick Company purchased the operation. Due damage to buildings in the hurricane of 1938, brick production ceased, but clay mining continued until after World War II. The site has been recommended as a National Register District by the Massachusetts Historical Commission. The Cook Brick Company was located at the end of Cook Street (#127) in the south end of town. Today it is run by the Stiles and Heart Brick Company and is the last operational brick company in Massachusetts. It is interesting to note that Stiles & Hart purchased the machinery of the defunct West Barnstable Brick Co on Cape Cod.

History of the Stiles and Hart Brick Company Stiles and Hart in Our Collection

SOURCES: |

Dempsey Brick Co.

Crescent, NY

Crescent is a hamlet in the town of Halfmoon, New York, north of Albany. It lies on the north bank of the Mohawk River in Saratoga County.

Crescent became the focus of economic development in the 1840's and 1850's, for it was here that the Erie Canal was carried over the Mohawk River via the Crescent Aqueduct. Supply stores serving canal operations were commonplace. William K. Mansfield, an early settler in Crescent, owned and operated a brickyard, using the canal to ship bricks to New York City. Soon there were other brickyards in Crescent during the late 19th and early 20th centuries including the Dempsey-Gabriels Brick Co. and A.C. Newton.

(SOURCE: NEW YORK STATE MUSEUM 59th ANNUAL REPORT 1905) |

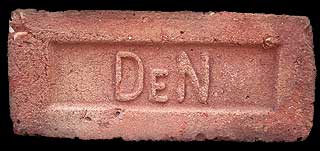

Dennings Point Brick Co.

|

DeNoyelles Brick Company

Haverstraw, NY (1870 - 1929) (13 machines in 1906) (found in Teaneck, NJ, and Haverstraw, NY)

|

Thomas Dinan

Fishkill/Ulster Landing, NY (1886 - 1900) (found in Spuyten Duyvil Shoreline Park, Bronx, NY) |

Donnelly Brick Co.

(found in Peekskill, Brewster and Patterson, NY)

Berlin, CT ========== From RootsWeb: CoTyroneIreland-L Archives

"Michael Henry Donnelly was born 1846. Came to the USA in 1866. He was a

successful businessman who had a blacksmith shop and later founded the

Donnelly Brick Company. This company thrived until the 1960's." ========== "Donnelly Brick Co., biggest clay producer in the county, worked its clay open pit near Kensington during the year." ========== From STEAM JULY, 1921:

"The Donnelly Brick Co., New Britain, Conn., plans the rebuilding of its. plant, destroyed by fire. The work will include a new machine department, dryer department, tunnel kiln building and other structures. Erection will be commenced soon."

|

Drury Brick Co. (raised letters in frog with CBMA symbol, photo courtesy of website visitor, Earl)  (raised letters in frog, courtesy of Shelburne Farms, VT)  (lowered letters in frog, courtesy of Shelburne Farms, VT)

Essex Junction, VT ========== How much is DRURY brick worth? ==========

The Drury brick house in Essex Junction, rebuilt in the 1860s, still stands on Main St. ==========

James Drury writes: I'm still a little sketchy on this part, but I think the first lettering appeared on water struck bricks when a metal stamp was included in the top (or bottom) of the brick form. I have what appears to be a water struck brick with this stamped style lettering. I also have sand molded bricks with this style, making this the transitional lettering style between the two manufacturing processes. I have one of these metal stamps but I'm only assuming this was used in the late 1880s to about 1910. I'm not exactly sure when the manufacturing process changed. Later bricks used a carved wooden DRURY that filled with clay to produce the raised letters. There are two versions of this lettering. The first incorporated the CBMA symbol after DRURY and I think was used between 1910 and 1920 but my dates may be off. While I have a sign dated 1917 that shows a brick with this symbol I do not have any of these wooden letter forms. The second version was used up until 1963 and did not incorporate the CBMA symbol. I have several of these wooden blocks. I'm still working on putting all this information together so please excuse the inaccuracies. ==========

In 1886, Dr. William Seward and Lila Vanderbilt Webb began acquiring farmland on the shores of Lake Champlain to create a model agricultural estate. They were assisted in the effort by two of the most prominent planners in the country: architect Robert H. Robertson and landscape architect Frederick Law Olmsted, Sr. By 1902, Shelburne Farms encompassed a 3,800-acre farm dedicated to demonstrating innovative agricultural and land use practices, a hackney horse breeding enterprise and a grand family residence. Case Study: Rehab and Restoration: DRURY brick at Shelburne Farms, VT |

Duffney Brick Co.

Mechanicville, NY (1910 - 1926) (thanks to Fred Rieck for this ID and to Jim Graves for researching the dates of operation)

"By the turn of the century, the Hudson Valley had become the center of the brick industry, with Mechanicville one of the leading production sites. Within a decade, six new companies (the Cory, Halfmoon, Stuyvesant, Hudson Valley, and Duffney firms) opened kilns, taking advantage of the demand for building and paving bricks in New York, Boston, and other population centers easily accessible because of Mechanicville's rail and canal connections.

"Today, there are few vestiges of this once flourishing industry other than one of the original yards of the Champlain Brick Co. opened in 1897, and a water pipe connecting the city water mains with the old Ferris-Duffney yards dating back to the beginning of this century." (View Reference)

From The Mechanicville and Stillwater Directory, 1911: |

East Shore Brick Co.

Verplank's Point (Verplanck), NY (1905 - 1910) |

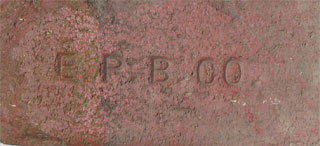

Eastern Paving Brick Co.

Catskill, NY (1895 - 1901)

There had been a big polution problem arising from

the smoke stacks that had the local people "smoking." The plant was shut down in

about 1901 for reason the "market bottomed out"... for a period of about five

years, resuming operation in about 1906.

Air pollution continued, and so did people's complaints. The chimneys were

subsequently heightened around 1910 in an attempt to mitigate the problem.

By 1912 production declined again.(Thanks to Fred Rieck for this info.)

On July 29, 1899, NY Governor Theodore Roosevelt signed an order to "Abate Nuisance, Matter of Eastern Paving Brick Co."

To see the complete order, Click Here.

|

Empire Brick Co.

Glasco, Newton Hook, and Stockport, NY, 8 machines at Glasco in 1910

(Found found at demolition site:

George Hutton in The Great Hudson River Brick Industry, states that Empire was forced out of business before 1940 due to exhaustion of clay resources in the Stockport area. The plant had undergone a thorough modernization in 1926 including new overhead cranes to load brick onto river barges.

|

Excelsior Brick Company

George H. Smith, Ira M. Hedges, Everett Fowler and Uriah F. Washburn Haverstraw, NY (1890) 13 machines

From: Portrait and Biographical Record of Rockland and Orange Counties New York,

Chapman Publishing Co., 1895: EVERETT FOWLER. The brick business is one of the principal industries of Rockland County, and the men who have engaged in it have almost invariably gained success. As a representative of this class mention should be made of Everett Fowler, who is superintendent of the Excelsior Brick Company and of D. Fowler & Son. The former concern has a capacity of sixteen million of brick and gives employment to eighty or ninety men, while the latter company employs seventy or eighty men, with a capacity in its output of twelve million. In the village of Haverstraw, where he still resides, Mr. Fowler was born December 26, 1854, and in the schools of this place obtained a fair business education; he afterwards attended, and was graduated from, the Thirty-fifth Street Grammar School in New York. At the age of eighteen he became bookkeeper for his father, and three years later he began in business for himself, opening a brickyard near his present location. After four years there, in 1880, he became a member of the firm of D. Fowler & Son, and has since managed the valuable plant of this company. When the Excelsior yards were purchased, he became a partner in the enterprise, of which he is now superintendent. His entire attention from early youth has been devoted to the manufacture of brick, and he has been unusually successful in this occupation. He has made a study of the business, and at different times has visited nearly all the brickyards in the United States, gaining from a close observation of their methods practical ideas for the management of his own yards. In April, 1880, Mr. Fowler married Miss Anna S. Denison, granddaughter of Major Suffern, and a daughter of P. and Anna (Suffern) Denison. Four children were born to our subject and wife: John E.; Catherine; Denison, who died at the age of four years; and Denton. Mrs. Fowler is a member of the Central Presbyterian Church, of which Dr. Freeman is pastor. In social circles Mr. Fowler is highly esteemed, and he is one of the active members of the Bicycle Club.

See Also: DENTON FOWLER.

|

William F. Felter (?)

Haverstraw, NY (1876?) |

Ferris Paving Brick Co.

Mechanicville, NY (found in landfill, Kingston, NY)

See also Duffney Brick Co. & Joe Bleau (above). |

Fiske & Co., Inc

Jonathan Parker B. Fiske, Massachusetts and Fiske & Co., Inc 1732 Flatiron Building, New York, NY

"Promoters and Designers of Artistic Brickwork"

(found at the Metro North RR Station, Yonkers, NY)

|

Denton Fowler & Sons

Haverstraw, NY (1880) 5 machines

|

Eugene Frost

Montrose, NY (1905) Croton, NY (1905 - 1910) At Croton, Eugene Frost also used the brand mark: EF.

|

M. B. & L. B. Gardner

(found in Hackensack, NJ by Ken Findlay, Findlay Landscaping LLC)  Hackensack, NJ (1901 - 1915) |

Theodore F. Gardner E. Kingston, NY (found among KB&ICo (Dwyer Bros.) just north of Steep Rocks)

Theodore F. Gardner, Kingston, is listed on page 28 of

|

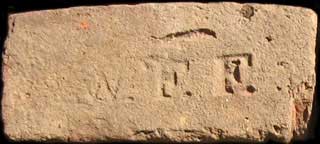

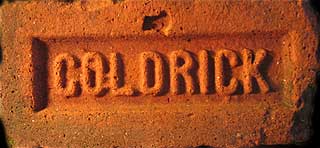

Gardner, Gardner & GardnerorGoldrick, Goldrick, Goldrick

Haverstraw., NY (1877) or Ulster, NY (1922) (found at Charles Rider Park, Ulster, NY)

In "Brick Brands of the United States" Jim Graves lists this as being Gardner, Gardner & Gardner but many G G G bricks have been found at or close to the site of the Goldrick Lower Yard. Thus we think the G's may stand for Philip, Thomas and Merton Goldrick.

The History of New York State Biographies, states: "In 1922 the name of the company was changed to that of Philip Goldrick & Sons, and Mr. Goldrick, who is the last survivor of the original brick manufacturers on the Hudson, continues as head of the concern, while his son, Thomas Goldrick, acts as production manager, and another son, Merton Goldrick, is in charge of sales and finance" A comment from Fred Rieck: "Perhaps the GGG's were mixed in stock that was transported from Haverstraw to the Goldrick's Landing/Rider Park area when Goldrick moved his entire operation out of Haverstraw in 1906." For much more info see GOLDRICK (below).

|

Garner Brick Works, Garner & Co.

Haverstraw., NY Garner operated Yard #17 in Haverstraw between 1903 and the late 1920s. The brick census in 1910 lists them as having 6 machines in 1910 (found in NJ by Ken Findlay, Findlay Landscaping LLC)

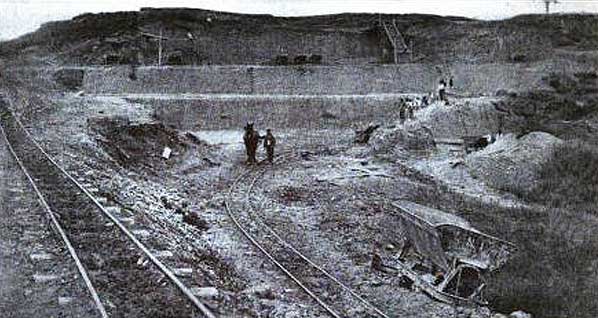

"The Garner yards extend along the river bank 740 ft. Not only is the Garner-yards' product of a high quality, but it is claimed that the brick at these yards are manufactured at a less cost, owing to the modern features of equipment. The two principal features are the oil-fuel system and the narrow-gage Kopple railway for conveying the raw material from the clay bank. This system includes nearly 5.000 ft. of track, 20-lb. rail being used. By means of turntables, cars can be cut out from the main track, switched off and emptied directly into the pit. The cars are of steel and each holds 36 cu. ft. They weigh when empty 900 lbs. each, and when tilled some 6,300 lbs., so that a train of three full cars would have a weight of about 19,000 lbs. Gravity is used for

handling them to a large extent. It is estimated that each of these trains would represent the work of four mules and four men, or a saving of about 70 per cent in the cost of transportation.

"The clay of the Garner yards is of a high quality and is taken from a bank 40 ft. in height, on which is an overburden of about 10 ft. in thickness. It is calculated that the clay deposit will last these yards for another century The output of the Garner yards is over 20 million brick per year.

"In the use of oil for burning, the Garner yards have taken a very progressive step in brick manufacture, and they have found the innovation of great economy and value. A tank on the river bank, holding 47,000 gals, of crude oil. is kept filled by the Standard Oil Co., who pump the oil into it from barges provided for the purpose. In burning the oil a small quantity of soft coal is used to start the fire, and the oil fuel is then introduced into the arches. in the form of a vapor, by means of a Sturtevant blower. These yards have been using oil for fuel since 1898, which ought to be proof of the success of this method."* |

Glen-Gery Brick

|

Philip Goldrick

Grassy Point (Haverstraw., NY) (1887), Kingston (Ulster), NY (1906), Saugerties, NY (5 machines in 1910) (found at Charles Rider Park, Ulster, NY just south of where Goldrick's Landing was located)

=In 1883, Mally & Goldrick operated a Yard #38 in Haverstraw and produced 4,600,000 brick with 2 machines,

employing 40 men. They leased the land from Adam Liburn. (History of Rockland County, J.B. Beers & Co., 1884)

=In 1887 Philip Goldrick operated Yard #39 in Haverstraw. Yard #38 was operated by Johnson & Meyers and Clark & Goldrick.

=On Jan 17, 1903 a brick census (inventory) was taken in the Haverstraw area and Philip Goldrick had 30 Arches with 1,400,000 brick on hand. =Goldrick was patentee of a Roof for Drying Sheds

=From: The History of New York State

Biographies, Part 12

A leader in the commercial and civic life of Kingston and vicinity, Philip Goldrick is one of the pioneer manufacturers who inaugurated the industry of brick-making in the Hudson River Valley, an industry which has been one of the principal factors in the material development of this district. Mr. Goldrick removed his entire organization to Kingston in 1906, and established the thriving settlement of Goldrick's Landing (town of Ulster), erecting his factories and brickyards, which produce thirty million bricks per year. He built homes accommodating two hundred and fifty employees, all houses of the most modern and improved design and equipment, opened mercantile stores and built a beautiful and impressive Roman Catholic church; in every conceivable manner, taking the deepest interest in the welfare and progress of his employees and the residents of the locality. His remarkable planning and foresight have made this a model community, whose inhabitants are noted for their industrious qualities and the intelligent and active interest which they display in issues concerning town or commonwealth.

|

Gladfelter & Gladfelter

Athens, NY (found by Bill in St. James, NY)

From the Tax Assesment records for Athens, NY for the year 1930:

|

Gormley Brick Company

|

Gormley & Son

Dutchess Junction, NY(?) (found in landfill along Rte 9W, Milton, NY)

|

William H. Haight

Poughkeepsie, NY (1900) (found in landfill along Rte 9W, Milton, NY)

Notes from Fred Rieck--

William H. Haight first appeared in Poughkeepsie City Directories in 1888 as a proprietor of a livery business at 21 Catharine St. His residence: 295 Mill St. In 1890 "sheds" appears as a business item along with livery and stables. 1900 directory indicates ... boarding and sale of horses a specialty, also farmers sheds, (and) Brickyard: 21 Catharine St. In the 1903-04 directory, he is no longer listed as having a brick affiliation The 1906-07 directory indicates an Ellsworth Craft is occupying the 21 Catharine St. address. Haight residing at 48 Academy. I never found a specific location for Haight's brickyard although I suspect it was somewhere around "Brick Yard Hill" in what is now Arlington. There is a Haight Ave. in that vicinity where Rts 44 and 55 diverge. There were three (3) William H. Haights in Poughkeepsie after Haight the bricker and liveryman moved in. Those other Haights were machinists - father and son Haight weren't in the brick business very long. There were a couple of pallets of used HAIGHTS between buildings between Main and Mill Sts. which may have fallen off a building wall in that area. These bldgs have been knocked down. None of the HAIGHT brick I've seen ever had a nice surface finish. Letters all were more difficult to read. ==========

Webmaster Notes-- Poughkeepsie, NY is rich in history. One of its notable citizens was Matthew Vassar who founded Vassar College in 1861. The Vassar Family emigrated from England to America in 1796 and established a farm in the Poughkeepsie area, overlooking the Hudson River. James Vassar made the transition from farming to running family businesses in the early 1800’s, founding a brickyard on their property and soon thereafter starting a brewery operation. He and his wife had two sons who grew up in the family businesses. In 1836 Matthew Vassar "commissioned a new waterfront brewery, which became the largest in the United States at the time, measuring 200 by 50 feet and producing 50,000 barrels of beer each year. While many businesses suffered during the 1837 depression, M. Vassar & Co. flourished due to an ongoing demand for ale. He also ran a brickyard which manufactured "large and beautiful pressed bricks" known as "Poughkeepsie Stretchers." Matthew Jr.’s widow, Irene Beech Vassar, inspired by Florence Nightingale, a well-known reformist nurse in Great Britain, set out to find a location for a new hospital and chose a piece of property on what was then the outskirts of Poughkeepsie. The 14-acre property had a perfect view of the river, pleasant grounds and therapeutic breezes -- perfect for patients and their recovery. Vassar Brothers Hospital opened its doors on April 11, 1887. The main building component was, of course, Vassar bricks.

Sources: Vassar Encyclopedia |

William K. Hammond

Dutchess Junction, NY (1905) 3 machines

For our Special Section on DUTCHESS JUNCTION Click Here.

|

Hammond & Freeman

Dutchess Junction, NY (1911) 4 machines |

Hanrahan Brick & Ice Co.

Ulster Landing, NY

From 1928: The History of New York State

Biographies, Part 12 Editor, Dr. James Sullivan. Online Edition by Holice, Deb & Pam: "James F. Dwyer, son of Denis and Johanna (O'Brien) Dwyer, was born in Kingston, May 26, 1859, and received his education in the public schools of Kingston, which, however, he left while quite a young lad, and engaged in the boating business on the canals, lakes and rivers of New York and other States. In 1887 he and his brother, Robert J. Dwyer, established a ship chandler's store in West Strand, where, in addition to the handling of ships' supplies, they also built boats, mostly barges and scows many of which operated themselves. Of both branches of the business Mr. Dwyer has been half owner since the death of his brother in 1925. The concern was incorporated in that year, just before the death of the brother, under the name of Dwyer Brothers, Incorporated, and at the present time (1928) they are also operators and owners of the following industries: The R. Lenahan Company, boat and barge builders; the Kingston Brick & Ice Company; Wilbur Sand Company; Hanrahan Brick & Ice Company; Dwyer Brothers Ship Chandlery, and the Arrow Ice Company.

James F. Dwyer owns and operates fifty barges on the Hudson River and in New York Harbor. He is principally engaged in freighting cement from Hudson River points to New York City, and in this branch of his varied interests he is meeting with substantial success. In financial circle in Kingston, Mr. Dwyer is active and influential. He has been president of the Rondout National Bank since 1924, and a member of its board of directors for the past twenty years."

|

Heitlinger & Company

|

Hudson Pressed Brick Company (?)

Hudson, NY

|

Hudson River Brick Company

Grassy Point (Haverstraw), NY (1920) 26 machines |

Patrick Hunt

Rosavilla, NY (1875) (found at the Van Cortlandt House Museum, Bronx, NY) |

Hutton Brick Company

William Hutton, East Kingston, NY (1891) 14 machines (found at the brickyard site, now Kingston Point Beach) (also found lining the cement kilns in Rosendale, NY) For our Special HUTTON Page Click the Brick. |

Juan Jacinto Jova

Danskammer Point, Roseton, NY (1884) (1/4 mi. north of Rose Brick Co.)

(Pic#1: taken in 2007 of a brick in a sidewalk at Provincetown, Cape Cod, MA

In the late 1800s, Juan Jacinto Jova (J J J) came from Cuba to New York City as a sugar broker, then moved up the Hudson River to Roseton, NY, where he had hoped to raise sugar cane. When that venture failed, he built a brick plant. Jova bought a large Greek revival granite mansion (Danskammer) from David Maitland Armstrong (who ran the ARROW Brick Co.) then tore it down to get the clay on which it stood. The grand pillars that supported the veranda of the house now stand in the sculpture garden of the Storm King Art Center in Cornwall-on-Hudson, N.Y." There's a lot more to the Jova story: In conjunction with our sister-site HudsonRiverHistory.com we have completed a new webpage:

A BRIEF HISTORY of ROSETON and DANSKAMMER POINT, NY

Here you will find a compilation of our research on the brickyards in this area: ==========

Jova Brick Works

Henry J. & Edward A. Jova Roseton, NY (1900) 14 machines (found in Pelham Manor, NY)

|

Jova Manufacturing Company

East Kingston, NY (1965)

|

Michael Kane Brick Company

New Park Avenue Hartford, CT (1872 - 1926)

654 Newfield St.

Webmaster Note: in February, 2008, we received this email from Mark Falco:

From BRICK AND CLAY RECORD, August 8, 1922:

From The Hartford Courant, February 07, 2010:

|

King Brick Company

Ulster Landing, NY (found in landfill along Rte 9W, Milton, NY also found at Charles Rider Park, Ulster, NY) |

Kingston Brick & Ice Company

Ulster Landing, NY (found in landfill in Kingston, NY

Owned by Dwyer Brothers, Incorporated. In 1928 they were also operators and owners of: The R. Lenahan Company, boat and barge builders; Wilbur Sand Company; Hanrahan Brick & Ice Company (see above); Dwyer Brothers Ship Chandlery, and the Arrow Ice Company.

|

Kreischer Brick Manufacturing Company

Kreischerville (Charleston, Staten Island), NY There were several firms in New York City that took advantage of the nearby deposits of fire clay and manufactured both clay retorts and fire bricks. In 1845 Balthazar Kreischer established a fire-brick works in Manhattan, later known as the New York Fire Brick and Clay Retort Works; Kreischer acquired a fire-clay deposit on Staten Island in 1852 and established a works there which eventually replaced the Manhattan factory (his son's house, the Charles Kreischer House and the workers' houses for the company, the Kreischerville Worker's Houses are both designated New York City Landmarks).

Kreischerville Map; Photos of Kreischerville mansion and streets paved with KREISCHER brick Kreischerville Workers' Houses

The Development of Kreischerville ========== The brick manufacturing firm that would later become B. Kreischer & Sons was founded by Balthazar Kreischer (1813-1886) in 1845. Kreischer was born in Bavaria and came to New York City in 1836, where he worked for a period as a mason. In the early 1850s, Kreischer was one of the first in the United States to produce fire brick, a fire resistant brick used in many industrial buildings. In 1853, Kreischer became aware of refractory clay deposits in Westfield, Staten Island. He acquired several tracts with clay deposits and purchased the rights to mine clay on nearby land. Two years later he established a brickworks on the Arthur Kill. As the factory expanded, the area became known as Kreisherville. By the time of Kreischer's retirement in 1878, the company had become a major producer of building materials in the metropolitan area. Kreischer's sons continued the firm, but financial problems forced them to sell the company in 1899. Peter Androvette, who owned a number of shipping concerns in the metropolitan area, including the operation that handled raw and finished materials for Kreischer, acquired B. Kreischer & Sons at foreclosure, reincorporating the company as the Kreischer Brick Manufacturing Company in 1902. This ushered in the company's heyday during the early twentieth century when it produced brick of all colors and types, along with ornamental terra cotta. The company's products were used by architects and builders throughout the East and Midwest. The company's prominence declined after the First World War, and the factory was closed in 1927. One of Kreischer's specialties was smokestack bricks, which were molded into trapezoidal shapes that produced circular stacks when laid side by side. This type of brick was used creatively in Ridgewood (Queens, NY) to create the curved bays that characterize many of its rows, including those in the Stockholm Street Historic District. Most of the Kreischer brick used in Ridgewood, including the Stockholm Street Historic District, is iron-speckled brick with smooth surfaces, laid with tight, flush joints. Also called iron-spot bricks, they were produced by adding manganese in a finely granular form. Rock-faced brick, also manufactured by Kreischer, was used in Ridgewood for details such as bandcourses and lintels. Builders in Ridgewood used Kreischer brick consistently until the First World War; after that, they used wire-cut bricks produced at factories in Pennsylvania. These bricks had rough surfaces and were laid with raked joints, producing a very different appearance. (from The NYC Landmarks Preservation Commission) ==========

And an article from our favorite archives at The New York Times dated November 24, 1892

|

William Lahey

Fishkill, NY (1889) Newburgh,, NY (1910) 7 machines

|

Lenox Brick Company

Cliffwood, NJ Found in the remains of the Boyce Thompson Institute, Yonkers, NY William Boyce Thompson, who acquired wealth in the copper mining industry, visited Russia in 1917 where he saw the effects of hunger on its inhabitants. This trip persuaded Thompson of the importance of ensuring food supply for the world population, and in 1920, he decided to establish the Institute for Plant Research across the street from his country estate Alder Manor, in Yonkers, NY. Over the years, Yonkers property taxes and urban pollution began to pose major problems. In 1978 the Institute moved to the campus of Cornell University. Plans to use the Yonkers site for a department store, office complex, low-income housing, a museum and a school have all failed. The brick buildings and greenhouses remain vacant today. NOTE: CBCo brick (Champlain Brick Co of Mechanicville, NY) were also found at this location as well as at Alder Manor (where this writer/Webmaster was married). ========== The IBCA's Jim Graves, citing the "Industrial Directory of New Jersey," indicates Lenox Brick was located in Cliffwood, NJ and its listing appeared in the 1909 and 1915 editions. ==========

From The Matawan Journal, Jan. 14, 1909:

"The Lenox Brick Company of Cliffwood, through George Craigen of Keyport, asked the committee to take some action relative to defining the road from the New York and Long Branch railroad near Cliffwood to Whale Creek. The road passes through the Gehlhaus property and north of the road from Keyport to South Amboy it is said to have been changed by reason of the excavation of clay for brickmaking purposes."

From The Matawan Journal, Dec. 30, 1909:

"The traction engine and two cars of the Lenox Brick Company were reported having become stalled on the public road near John F. Selover’s at Cliffwood last Friday and that it was difficult for wagons to pass them. After some discussion it was decided to have Road Superintendent Harvey Stillwaggon notify the company to remove the obstruction as soon as possible."

(SOURCE: AberdeenNJ.org

==========

"Aberdeen Township Street Names" states

Lenox Road was named for the Lenox Brick Company. The road was laid out in July, 1914 on a map of Keyport Heights. |

Robert Lent

Coeymans, NY (1904-1920)

ROBERT LENT was born at Glasco, N. Y. on November 22, 1892, He came from a family of brickmakers. His grandfather ROBERT LENT was born at Highland Mills, Orange County, N. Y. on May 3, 1828 and was a brick manufacturer at Glasco, Ulster County, N. Y. He married Catherine Conklin, of Orange County, N. Y., November 20, 1852, at Matteawan, NY. DAVIS CALEB LENT was born at Naugatuck, New Haven Co., CT on Oct. 31, 1854, He was manager of the Denning's Point Brick Works. Mr. Lent was the first to burn brick with anthracite coal, which was done on his father's yard at Glasco. He had thorough business abilities, and was one who understood the brick making industry in all its details perfectly. He was married to Mary E. Seaman, of Ulster County, N. Y., JOHN WRIGHT LENT was born at Naugatuck, New Haven, Co., CT, on March 9, 1859. He was manager of his father's brick making business at Glasco, N. Y. WILLIAM LEWIS LENT, born at Naugatuck, New Haven Co., CT on August 20, 1863, was engineer for the Denning's Point Brick Works. He married Mary E. Felter, of Ulster County, N. Y.

SOURCE: "History of the Lent family in the United States, genealogical and biographical," 1903,

by Nelson Burton Lent.

|

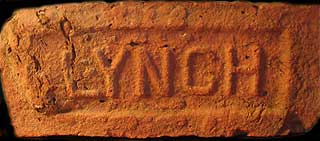

Lynch Bros.

Ulster Landing (East Kingston), NY (5 machines in 1910)

Patrick Lynch operated Yard #4 (owned by Daniel DeNoyelles) in Haverstraw from 1887 to 1896. The Lynch Brothers operated this yard in 1903. In 1910, O'Brien and Lynch operated Yard #11 and John Lynch worked Yard #22. In Within These Gates Daniel deNoyelles lists the Lynch Brothers operating 5 machines in "the Kingston district" in 1910. This brick was found along the west Hudson shore near Ulster Landing at what may have been the brickyard site.

|

Patrick J. Lynch & O'Brien

Haverstraw., NY (1902 - 1910) In 1910, O'Brien and Lynch operated Yard #11 in Haverstraw. See also OBRIEN.

|

|

FYI World Media © 2005 - 2022 D.S. Bayley

Hudson River Brickmaking |

Brick History/How Bricks Were Made

|