|

HUDSON RIVER & NEW ENGLAND

A collection of Hudson River & New England Brick with a brief history of the yards and towns where they were made.

|

Search This Site For Brick Info: |

To search the page you are on, Hit CTRL-F |

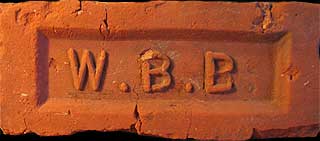

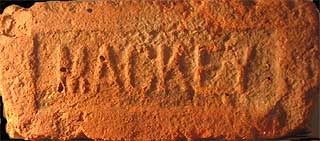

Mackey Yards Brick Company

Verplanck, NY (1895 - 1905) 4 machines in 1910 (found near the brickyard site)

|

Robert Main & Company

Saugerties, NY (1905) 4 machines in 1910 (found at Wave Hill, Riverdale, NY) |

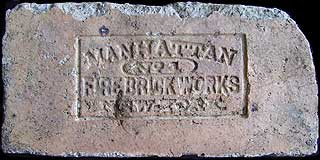

Manhattan Fire Brick Works

New York City, NY and Maurer, NJ found in Nutten Hook (AKA Newton Hook), NY. (NOTE: the R. & W. Scott Ice Company was located in Nutten Hook. The remains of the powerhouse are still there.) The Manhattan Fire Brick and Enameled Clay Retort Works (as described in New York Illustrated (New York: D.Appleton & Co., 1876) was located on East 15th Street near the East River. Henry Maurer learned the fireclay manufacturing business in his uncle's firm, Maurer & Weber, and then established his own firm which relocated from New York and Staten Island to Maurer, New Jersey, in 1874 There were several firms in New York City that took advantage of the nearby deposits of fire clay and manufactured both clay retorts and fire bricks. In 1845 Balthazar Kreischer established a fire-brick works in Manhattan, later known as the New York Fire Brick and Clay Retort Works; Kreischer acquired a fire-clay deposit on Staten Island in 1852 and established a works there which eventually replaced the Manhattan factory (his son's house, the Charles Kreischer House and the workers' houses for the company, the Kreischerville Worker's Houses are both designated New York City Landmarks). Joseph K. Brick established the Brooklyn Clay Retort and Fire Brick Works in 1854. The Maurer & Weber Company later known as the Manhattan Fire Brick and Enameled Clay Retort Works, opened in 1863. In 1868 John Cooper established a business, later known as the Greenpoint Fire Brick and Sewer Pipe Works, at 413-421 Oakland Street, Brooklyn. While there were 350 fire brick manufacturers in the United States in 1895, the New York-New Jersey area remained one of the major fire brick manufacturing centers.

Some biographical information:

WEBER, Adam (1825-1906) studied architecture in Germany before coming to this country in 1843. After working in architects' offices for some years writing specifications and overseeing buildingconstruction, he established his own building firm. In 1845, Weber helped Balthazar Kreischer toestablish Balthazar Kreischer & Company, one of the city's leading brickworks. (Weber married Kreischer's daughter Katherine Elizabeth in 1858.) Weber and his cousin Henry Maurer formed apartnership in 1857 to manufacture fire brick (fire resistant brick used in many industrial applications)and clay retorts (which were used in the manufacture of gas lighting). In 1876, the partnership was dissolved and Adam Weber established his own firm, the Manhattan Fire Brick Company, which specialized in the production of products for gas works and breweries. See Theodor Lemke, Geschichtedes Deutshthums von New York (New York: T. Lemke, 1891-92), Adam Weber obituary, New-Yorker Staats-Zeitung, Dec. 23, 1906

MAURER, Henry, manufacturer, was born in Hornbach, Rhein-Pfalz, Germany, March 19, 1830. He attended school until the age of fifteen, when he went to Paris, France, to learn the trade of cabinet making. At the age of eighteen he came to New York.

Trade was dull in his line, yet he obtained employment with an uncle, Balthasar Kreischer, a manufacturer of fire brick. By force of merit he soon advanced to the position of foreman ; a few years later to that of book-keeper, and at the age of twenty-six became a partner in the firm under the name of B. Kreischer & Nephew. In 1863 he sold his interest and formed a partnership with Adam Weber, establishing the Manhattan fire brick works under the firm name of Maurer & Weber.

Not satisfied, Mr. Maurer after some time sold out his interest to Mr. Weber, bought the Forbes estate near Perth Amboy, N. J., and started a factory of his own. He introduced the newest and most perfect machinery, all of his own make and invention, and in a few years had the consciousness of owning the largest factory of its kind in the United Slates: clay gas retorts, tiles and blocks for use in blast furnaces, rolling mills, steel works, etc., He turns out every year 50,000 tons of material and employs 350 men. The leading architects of New York and other great cities use his fireproof material for their buildings. He does a large export business to distant parts of the world, including China and South America. Adjoining his works he built a village: dwellinghouses for his workmen, also a school house, railway station, and hotel. It is known under the name of Maurer, N. J., on the Jersey Central railroad. Mr. Maurer takes a keen interest in public affairs and especially in education, and was for seven years a school trustee in the seventeenth ward in New York city.

From the NYTimes, April 15, 1898, Wednesday, Page 9: WEBER, N.J., IS NO MORE.; Name Changed to Keasbey After a Long Fight Between Rivals.

NEW BRUNSWICK, N.J., April 14. -- Weber, Middlesex County, is no more. Postmaster General Gary has ordered that the name of the village between this city and Perth Amboy be changed to Keasbey, and this mandate goes into effect July 1. This is the outcome of a bitter fight waged for several years between the Raritan Hollow and Porous Brick Company and the Manhattan Fire Brick and Enameled Clay Retort Works.

|

Joseph Mayone

Glasco, NY (Incorporated 1916) (found near Orchard Beach, Bronx, NY) On July 1, 1925, Joseph Mayone took possession of the Freeman property, West Bridge street (Powder Spring Farm), formerly owned by Frederick Cooke. Mayone operated yards at Athens, Catskill and Glasco.

Excerpts from "The Gentleman from Ulster."

Mayone family notes on the brickyard and its founder |

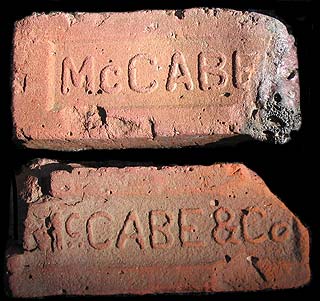

Frank J. McCabe

Ulster Landing (East Kingston), NY These bricks were found along the west Hudson shore near Ulster Landing at what may have been the brickyard site. |

Terence McGuire & Son

Haverstraw, NY (found in a discard pile off Rt 22, Millerton, NY)

(Thanks to Fred Rieck for this ID via the Haverstraw Brick Museum (Tom Sullivan). The reason the lettering came out backwards was because the letters were stamped (or maybe branded in with hot iron) so they read correctly when viewed in the mold. However, when clay was added to the mould it filled in the indentation and after the brick was released from the mould, the letters on the brick read backwards. Brickmakers sometimes forgot that the brand had to be enscribed backwards in the mould in order to come out correctly on the brick. ==========

Terence and Pat McGuire leased Yard #22 from Mrs. E.G. Reid. They also worked with Thomas DINAN.

Terence's daughter married David Butler, another Haverstraw brickmaker.

|

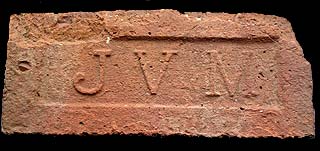

James Van Duser Mead

found in Castle Point, NY (perhaps near the brickyard site) A note from Jack S. Meade: My roots are in the Hudson Valley and my ancestors owned a brick building business. I am searching for historical information and am contacting you to see if you can provide any factual information on the business. To date I have not been successful in uncovering any historical information that I seek. My grandfather, Sebastian Sommers Meade was born in Chelsea on the Hudson, NY. He was a founding member of the Chelsea Yacht Club and owned and operated a brick building business in the Chelsea, Fishkill, Pougkeepsie area for 30 plus years before terminating it in 1934. He inherited it from his father, James Van Duser Mead who inherited it from his father, Justice Mead who started the business in the Tarrytown NY area. The name Mead became Meade after James Van Duser Mead passed the business onto my grandfather. Would your archives contain any information on the family brick business or, if not, can you suggest an historical source whom I can contact. Thank you. A Reply: Hello Jack. Thanks so much for sharing that piece of Mead / Meade history with us. As I understand it, the Mead came before the Meade, which I find quite interesting. Would you recall what brand names your grandfathers may have placed on their brick?

Somehow I gained the impression that your Grandfolk's yard may have been part

of what is now the Castle Point Veteran's Hospital. Does that match any

understanding that you may have come to?

Again, Thank you

Webmaster Note: |

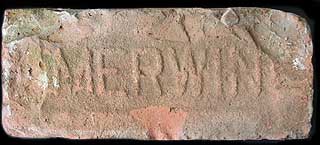

Charles P. Merwin

Berlin, CT and Long Island, NY (found by Bill Q. in St. James (Long Island), NY)

Webmaster Note: I want to thank Bob for his invaluable contribution to this web site. This is a unique historical documentation and adds considerably to the total experience visitors here can enjoy.

|

Montowese Brick Company

North Haven, CT (1899-1933) (found in Van Cortland Park, Bronx, NY) ID Source: Jim Graves

A good combination of geographical attributes aided and assured the oncoming settlers of a good means earning a livelihood for their families. The flat fertile soil along a river's edge and the gently rolling hills enticed the crop and dairy farmers to extensive acreage. Clay beds beneath the salt marshes spurred the growth of the red brick-making industry to be rivaled as the principal industry only by growth of Cedar Hill Railroad Classification Yards. All of these guaranteed the continuing growth of the village.

Source: https://www.sttheresenoh.com/History.htm

|

Richard A. Moore

(found by Andy Van DerPoel) From The History of New York State, 1927: One of the leading citizens of Mechanicville, Richard A. Moore takes a prominent part in the industrial and business life of the town, being treasurer of the Dufney Brick company and the R. A. M. Brick Company, as well as vice-president of the First National Bank of Mechanicsville. At difference times he has been selected to serve on commissions whose purpose was to improve in one way or another conditions in the town. He is the son of Pierce Moore, born in Waterford, Ireland, on June 22, 1839, died in Mechanicville, in 1879; and of Bridget (Sweeney) Moore, a native of Waterford County, Ireland, now a resident of Mechanicville. The father came to the United States when a young man, and settled in Mechanicville, where he was employed in the mills until his death. Their children included three who are now deceased, but those living are: 1. Mary, the wife of Henry Madigan, of Mechanicsville. 2. Richard A. 3. Ellen, who married Mr. Rolph, of Syracuse. Richard A. Moore, born in Mechanicville, New York, November 8, 1871, was educated in the Mechanicville and Stillwater public schools. He was first employed in the Duncan Mills, in Mechanicville, where he remained for four years; and afterwards he was for twenty-two years a salesman fro the Dobler Brewery Company. In conjunction with this work he conducted a retail store in Mechanicville, for thirteen years. In 1910 he became associated with the Dufney Brick Company, of which he became treasurer in the following year and has been treasurer ever since that time. He is also treasurer of the R. A. M. Brick Company, of Mechanicville, and vice-president of the First National Bank. At one time he was a member of the sewer commission, and later was supervisor of canals in Mechanicsville. He is a director of the New York State district of the Common Brick Manufacturers' Association; a member of the Foresters of America; a member of the Benevolent and Protective Order of Elks, in which order he is affiliated with Lodge No. 1403, of Mechanicsville; and the J. L. Short Hook and Ladder Company for twenty years. He belongs to St. Paul's Roman Catholic Church. Richard A. Moore married, in Mechanicville, Katherine Goodspeed, the daughter of George and Sarah A. (Bissell) Goodspeed, born resident of Schoharie County. The children by this marriage were: 1. George, Deceased. 2. Katherine, deceased. 3. Nellie, deceased. 4. Mary. 5. Ethel. 6. Pierce. 7. Anna, and 8. Margery.

|

Morrissey & Company

Grassy Point (Haverstraw), NY 5 machines in 1910 (found by Bill Q. in St. James (Long Island), NY)

|

John Morton

Croton Landing, NY In Croton Landing, George Morton & Co is listed in: New York State Business Directory and Gazetteer, 1870: and John Morton in: History of Westchester County, 1886,

From the N Y Times, Feb 24, 1912: There is also a John Morton in Montrose and Verplank mentioned in New York State Museum's MARCH 1895 CLAY INDUSTRIES OF NEW YORK: "Along the New York Central Railroad tracks a short distance south of Montrose station are the yards of C. Hyatt and J. Morton. Mr. Morton also has a covered yard on Verplank Point where front brick are made. Their banks are practically a continuation of each other. The clay is both blue and yellow and is overlain by several feet of coarse sand. Hyatt uses steam power and Morton horse power to run his machinery. The bricks are loaded on cars and shipped to various points along the Central Railroad."

Webmaster Note:

Many thanks to Rob Yasinsac of hudsonvalleyruins.org for a tour of the Woody Crest ruins.

|

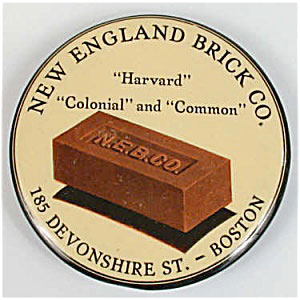

New England Brick Company (found in Spuyten Duyvil, NY)

New England Brick Company (for more info, Click the Brick!)

|

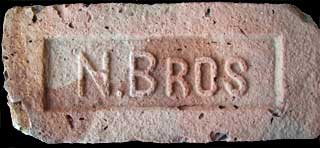

John Nicholson

Haverstraw, NY (found by Ken Findlay, Findlay Landscaping LLC)

"My name is John Nicholson. I believe my grandfather and his brothers owned a brick factory down in Haverstraw. If I remember correctly the names on bricks were: N Bros and Nicholson. I don't remember the N one that you show. I was a kid, so I am vague about it. I have a few Nicholson bricks, one is pictured Here. If you would like it in your collection, please let me know. Any information you have on the Nicholson Brick factory would be appreciated." |

Nicholson Brothers

(found in landfill along Rt. 9A in Milton, NY)

|

Pierre A. Northrip

Dutchess Junction, NY

A 1905 NY State Mining and Quarry report lists Pierre A. Northrip as a Newburgh, NY manufacturer with his plant located at Dutchess Junction, NY. Other research indicates that there was a Pierre A. Northrip on the staff of one of the NY State prisons. |

Patrick O'Brien

Verplanck (Montrose), NY, 3 machines Found at the brickyard site, now Montrose Point State Forest, off Kings Ferry Road. We also found OBRIEN in the ruins of the Peekskill Centennial Hose Firehouse (see below).

(Source: https://eaglepark.org/History/History_P1.htm) |

O'Brien & Vaughey

Fishkill Landing and Verplanck, NY Found in the ruins of the Centennial Hose Firehouse, Peekskill, NY

Other bricks found in the firehouse ruins:

N.Y. Times article on Centennial Hose 1893 Map showing Centennial Hose and Horton & Mabie Firebrick Works "Hudson Valley Ruins: Peekskill" Video of Firehouse Collapse from News 12 ========== From The Murray Tree: A Family History, The Vaughey Family:

"Around 1725 a man named Alexander Vaughey came from the city of Omagh in County Tyrone to a the town of Slane in County Meath, Ireland.

The family continued to live in Slane and around 1840 James Vaughey married Margaret Conlon and they left for America. I have no idea what brought them to Verplanck, New york, but it was probably the fact that the brick-making trade was heating up then and labor was needed. James and Margaret had eight children, of of whom was Bridget, born in Verplanck on September 3, 1847 and was my great-grandmother. Their other children were Bernard, John, Margaret, Christopher, Jane, James and Thomas.

"Thomas was involved in the brickmaking industry. Other brothers may have been also. I have checks made out to Tom from the First National Bank of Sing Sing from the firm of "OBrien, McConnon & Vaughey" who I believe were brickmakers. There are five checks totaling 1275 dollars, the smallest being 150 dollars. This might not seem like much money today but the fact is that the average worker at that time was making about one dollar a day!" ==========

|

John Paye

Fishkill, NY (1899) (found in landfill along Rt. 9A in Milton, NY)

From: Sloops of The Hudson

Captain Paye assures me that he once made the run from New York to Dennings Point (on Newburgh bay), fifty-eight miles up, in four and one half hours with the schooner Harriet Ann. Once, in 1868, he left Hamilton Ferry, Brooklyn, with the sloop Commodore Jones at nine p. M., wind east-northeast, went to Fishkill, and was back at Hamilton Ferry at eight P.M. next day. Of the twenty-three hours' interval, four were spent in loading." ==========

Chelsea Yacht Club Chelsea, New York

The "Paye" bricks...are from the brickyard run by Captain John Paye who died in 1909. He was a Hudson River sloop captain who retired to make bricks (Fran Laffin, letter Oct. 30, 1989)." |

Peck Brick Company

Haverstraw, NY

According to Daniel deNoyelles' book, "Within These Gates," the Peck Company produced high-quality brick. "They usually demanded a higher price for their brick for they took extra care, making an excellent facing brick," he wrote. The Peck Company was also one of only a few manufacturers that produced brick inland. Its bricks were transported via a "narrow gauge railroad" from its brickyard to its pier, Peck's dock. ========== From: Preservation (the magazine of the National Trust for Historic Preservation), July, 2002 "Fire Destroys N.Y. Mansion" by Augustus Rylands: "After three decades of neglect, the historic Henry M. Peck house in West Haverstraw, N.Y., 35 miles north of New York City, burned down on July 3, just as a project to restore it was about to begin. The mansion was built in the 1860s for Peck, whose family owned a brick-manufacturing business and who in 1852 was elected a trustee of the village of Haverstraw, then known as Warren. In 1931 the state purchased the building as a home for the superintendent of a nearby hospital. Peck's house fell into disuse in the 1970s and was boarded up, but recently the hospital's foundation launched an effort to restore it." On his website HudsonValleyRuins.com Rob Yasinsac has a photo of the Peck Mansion.

|

Norton I. Pennock

Arlington (Poughkeepsie, NY) (found in landfill, Arlington, NY)

|

Pickering & Malcoff Brick Co.

Glasco, NY

|

Pleasant Valley Brick Company

South Windsor, CT (found in Pelham Manor, NY) |

Poughkeepsie Brick Corp.

Arlington Poughkeepsie, NY(Poughkeepsie), NY (found behind house renovation in Poughkeepsie, NY, 1 block away from site of the HAIGHT Brickyard: 21 Catharine St) From Fred Rieck: Poughkeepsie Brick Corp. is about the last yard to operate on "Brickyard Hill." In a 1929 city directory, Poughkeepsie Brick Corp debuts, sited on Van Wagner Road nr. NYNH&HRR in Arlington. The directory lists the principals of PBCORP as Walter J. Travis (pres); W.N. Wetterau (V. P.) and John B.Vanderwater (Sec'y). J.B. Vandewater is also listed as an "Attorney-at-Law," George H. Terwilliger had become Sup't. and Otis A. Allen was Treasurer. Webmaster Note: For more info on Poughkeepsie brickmaking, see HAIGHT.

|

Powell & Minnock Brick Co.

Route 144 Coeymans, NY (1905) 5 machines

P & M Ruins

Many efforts were made to try and stay in business:

In 2000 an award from NY State ERDA of more than $4,000 was granted to Powell and Minnock. Annual energy bills for the facility exceed $1.6 million. NYSERDA's award helped to fund an efficiency study of the facility that recommended a number of ways the company could lower its energy costs, including lighting upgrades and retrofits, installing more efficient electric motors, and modifying the kilns used to manufacture the bricks, which would allow 63% more bricks to be processed through the kilns each day. These recommendations could save Powell and Minnock about $640,000 per year. The total cost to implement these recommendations will be a little more than $1 million, which will be covered by the energy savings in less than two years.

==========

The Powell & Minnock Brick Company CLICK HERE ==========

The Powell and Minnock Brick Company is featured in:

~ Kenneth T. Jackson, Jacques Barzun Professor of History, Columbia University |

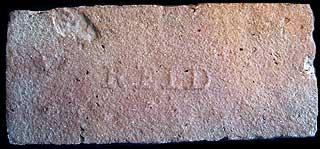

Patrick Reid

Haverstraw, NY (found at Haverstraw Bay County Park)

Sources: Fred Rieck, Jim Graves/IBCA, David Rumsey Collection/Cartography Associates

|

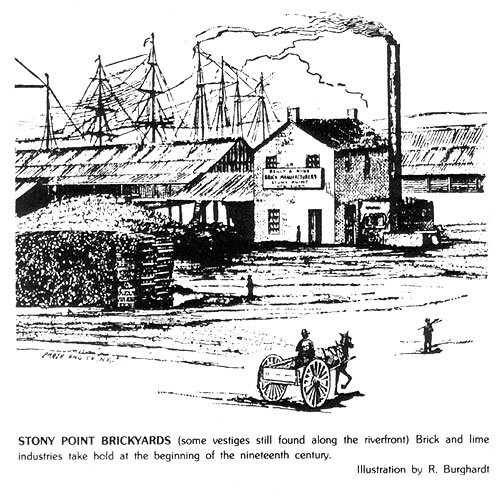

Reilly & Rose

Stony Point, NY (1883) 3 machines

From Stony Point Illustrated, 1888:

the son of Alax. Rose and Nancy Springsteed, is a member of the

firm of Reilly & Rose, who are successful brick manufacturers.

He is a grandson of Jacob Rose, and his great-grandfather was of

Revolutionary notoriety ; his mother is the faithful keeper of the

Lighthouse, and has been so for 31 years ; he is a descendant of

the Parkerson and Storms families ; his sisters are Lavinia and

Melinda. Republican ; Presbyterian.

|

Edward N. Renn Brick Company

Haverstraw, NY (1895) 4 machines (found on the Upper West Side, NYC) |

Richmond Brick Company

Fresh Kills Rd., Green Ridge, Staten Island, NY (found by Jason in the Bronx, NY)

From First Annual Industrial Directory of New York State, 1912

"Green Ridge: Richmond Brick Co, Fresh Kills Rd.,

To see the actual directory page, Click Here. |

Rockland Brick Company

Haverstraw, NY (1941) Last manufacturer of brick in Haverstraw Bay area |

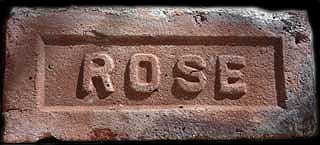

Alonzo Rose & Co., Rose Bros.

(found at or near the brickyard site, Ulster Landing, NY)

Alonzo first resided in Stony Point, NY and most likely was involved

with the Reilly and Rose yard there. (Scroll up to see Reilly and Rose.) He then moved to Dutchess Junction (see article below) and soon

opened a brickyard in East Kingston in the 1890s

ALONZO ROSE, a native, but now residing at Duchess Junction, was born 1840, and is the son of J. I. Rose and Rebecca Knapp. The names of his grandfathers are Henry Rose and Abel Knapp; Mrs. Abbey Phillips was his grandmother. His only brother is Newman ; the sisters are Almira Fales, Abby, wife of Capt. Jas. Leet, and Mary. Mr. Rose married Miss Emma J. Wilkins, Nov. 22, 1865 ; the children born to them are Irving J. and Alonzo K. He is a successful brick manufacturer. The citizens of Stony Point reluctantly parted with the family when they removed to Dutchess Junction. Prohibitionist ; Methodist. ROSE is from Dutch Rozee, the favorite name of a female. The French word Rozet is pronounced ro-ze.

|

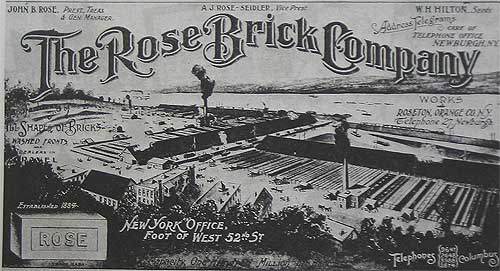

Rose Brick Company (found by Bill Q. in St. James, NY)

John C. Rose (1884)

At its peak, The Rose Brick Company sold 400 million brick a year worldwide. Architects and builders recognized the superior quality of Rose-made brick. Rose Bricks were used in the Ansonia and Bell Nord Hotels, the Customs House at the Battery as well as the Empire State Building, the Linden Apartments in Riverdale, the Stock Exchange, the Singer Tower (now gone) and the Waldorf Astoria. John Bailey Rose and his father John C. (who founded the company in 1884) built a company town, Roseton, NY. In The Great Hudson River Brick Industry George Hutton writes, "Rose created a community for workers that included an attractive commons building (featuring club rooms, a reading room and billiards) and a very proper-looking brick schoolhouse. None of those buildings exists today." In conjunction with our sister-site HudsonRiverHistory.com we have completed a new webpage:

Here you will find a compilation of our research on the brickyards in this area (ROSE, JOVA and ARROW).

|

SAGE Brick Manufacturing Co.

Greenport (Southold) (Arshamomaque), NY (1887 - 1938)

From BRICK-MAKING IN SOUTHOLD: It may be little known that the one of the most significant exports from Fishers Island during the mid to late 1800s was high quality bricks. The exact date of discovery of the vast clay deposits on Fishers Island is unknown, however, prior to the 1800s, the clay deposits possessed many evidences that bricks and other items were made throughout the history of the island. The first identifiable brick on the island, however, was crafted by Eugene Strickland but it was not until the arrival of the prominent Connnecticut businessman, DeWitt Clinton Sage, that the clays of Fishers Island were memorialized in New England architecture and municipal projects. DeWitt Clinton Sage was born in Middletown, Connecticut in 1837 to Barzella and Elizabeth Sage. He learned the brick making business at an early age working as an apprentice to his father. When he was sixteen years old his father died, leaving him to manage the developing brick making business. After successfully conducting the business for six years he sold it and then focused much of his time on making machinery, a trade in which he was quite successful. While on business overseas, he became interested in machining munitions and upon his return home he succeeded in developing a new cartridge for the war department. So how did Dewitt Clinton Sage arrive on Fishers Island? Ironically, following the closure of the munitions factory Mr. Sage was able to secure another contract manufacturing headstones for the national cemeteries. It was near the end of this venture that he fell ill and ventured to the island to convalesce. While on the island he met Eugene Strickland (the local brick maker) and bought the clay deposits between Clay Point and Hawks Nest Point with every intention of starting a brick making yard. Mr. Sage's solid experience and business sense rapidly catapulted brick making on the island to a tremendous scale. In 1879 The Mystic Press reported that 2,500,000 bricks were delivered every season. In 1883 The Brooklyn Eagle reported that the yard has gone into a 'possession of a stock company' electing Mr. DeWitt Sage as the president. He continued this venture for 10 years then decided to set his sights on the Southold mainland. Fishers Island bricks were of superior quality and were sought after to comprise the exterior of many accomplished buildings and projects. The City of New York ordered 25,000,000 bricks for a new aqueduct to supply water to the population. As a testament to the quality of clay on Fishers Island, all of the three Winthrop houses were constructed of Fishers Island brick including the Mansion House and Brick Yard house which is reportedly filled with spirits (not the drinking kind). Interestingly, the clay deposits on Fishers Island were vast and in some areas occurred to a depth of 40 feet. Interestingly, the composition of the clay was found to be almost exactly to that found at Pipe's Neck in Arshamomaque on the Mainland. In 1887, The Long Island Traveler reported that the Fishers Island Brick Yard was one of the largest in the United States. Advertisements for the enterprise boasted the capacity of 18,000,000 bricks per annum and shipping to 'Any port on the coast.' The works could produce more that 400,000 bricks per month with each Scove kiln requiring 50 cords of wood and six days burning.

It was this same year that Mr. Sage purchased 180 acres of land near Greenport

where Brick Cove Marina is located today to begin the Long Island Brick Co.

Mr. Sage brought in large cranes and an army of men to mine the clay deposits,

notably a boost to the local economy.

The clay was mined over the years, separated from the Peconic Bay by a earthen dike.

Success followed Mr. Sage; in 1899 a staggering 30,000,000 bricks

were ordered for the construction of the State Hospital at Central Islip.

==========

From FamilyTreeMaker: Patrick O'Neill (b. 1856):

|

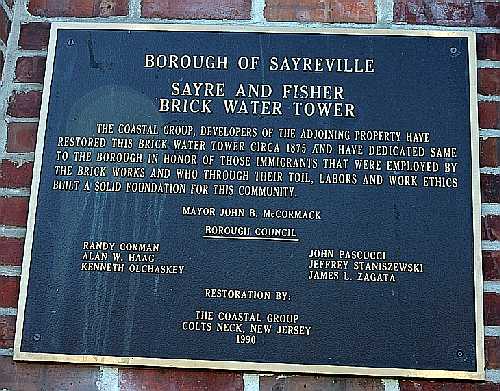

Sayre & Fisher Brick Co. (found by Jason & Chris in the Bronx)

(From the Fred Rieck Collection)

Sayreville, N.J 1850-1970s

Sayre & Fisher continued to grow and expand its market. By 1913, they were turning out 178,000,000 bricks per year! When the company celebrated its 100th anniversary in 1950, it estimated that they had made 6,250,000,000 bricks, enough to build over 400,000 modern homes. The Sayre & Fisher Brick Company continued to turn out bricks in Sayreville until the 1960's, when the plant was closed. You can still see some of the brick "company houses" built for employees along Main Street in Sayreville, and one of the smokestacks still stands in front of the Winding River Development where the plant was located." Various Brick Styles from the S & F Company

Ed Pytel, Sayreville Historian, writes:

John Cunningham noted in his

book, Made in New Jersey, that the Sayre & Fisher Co.

released a production statistic of 178 million bricks in

1913. The Sayreville plant became the largest brickworks

in the world. Sayreville bricks were used in the

construction of many buildings in the eastern states that

included the Empire State Building in New York City

and the Statue of Liberty. The company closed its brick

manufacturing operations in the early 1970s."

The Sayreville Historical Society contains a large collection of memorabilia, including contracts, brick samples, and company brochures of the Sayre & Fisher Brick Co.

Glimpse of History: Sayreville, Brick by Brick

|

C. Schleede Brick Co. Ulster Park, NY 1905 From NYS Division of Coastal Resources:

The subunit contains several historic houses and estates located along River Road. At the corner of River Road and Broadway is a wood and stone house built in 1767 and restored in 1941. This was the Van Vliet homestead, one of the early settlers in the area. The house was known as the "Jug Tavern" during Revolutionary times, and George Washington was reputed to have stopped there. Inland from the old Schleede Brickworks is the site of the stone house built in the early 18th century by James Niese on a land grant from Queen Anne. This now is the site of a more modern home. Several of the historic estate structures are intact, set in a well-maintained estate landscape of sweeping lawns. " Additional area information is available at the Klyne Esopus Museum web site.

Here's a link to a Maps Live.com "Bird's Eye" view of brick fragments along River Road and the West Hudson shore near Ulster Park.

|

George A. Shahan Glasco, NY (found at or near the brickyard site) |

Thomas Shankey & Son

Haverstraw, NY |

Shares Brick Company Hamden, CT (found at the Bray Farm on Cape Cod, MA) ========== Although the precise date of the first efforts to make brick within the limits of the town has not been ascertained, it is certain that they were made on the western border of the Quinnipiac, a few miles below the North Haven line, a century or more ago. The clay for the first kilns was carted southward for two or three miles from at, or near, the north line of the town, the road leading over what has since been proved to be a nearly continuous deposit of brick clay. Two yards were established near where the present Quinnipiac station is, and were worked for several years, but both were finally abandoned. About 1870 Mr. H. P. Shares opened a clay bed and commenced burning brick, and since then Capt. Crafts, and four or five others, have established brick yards, with present total capacity of from twenty-five to thirty millions of bricks annually. More bricks are made in the town of Hamden than in North Haven. According to Barber, in 1836, the brick industry of the Quinnipiac valley, partly in the town of North Haven, reached the extent of four and a half million bricks annually. The railway gives great facilities for the transportation of these brick, and they are sent all over the State and even to New York. The clay is well adapted to the manufacture, and it is claimed is not surpassed by any brick clay in the country. The color is good and uniform. The shrinkage in burning-is slight, and the brick hold their form without twisting and warping. The good qualities of these brick are becoming better and more widely known, and the demand for them is increasing. Until recently the fuel for burning has been chestnut and other hard woods, consuming from five thousand to six thousand cords annually. This incessant and increasing drain upon our forests is now somewhat lessened by the substitution of bituminous coal, which, for eighteen months past, has been successfully used by Capt. Crafts and found to be cheaper than wood. Brick moulding machines have re placed the slow process of moulding by hand, and the green brick are dried upon shelves instead of upon the ground, as formerly. In the production and delivery of one thousand brick twenty-two tons weight are handled. Each thousand weighs two tons, and the material is handled eleven times. Quinnipiac brick are now worth from $6 to $7 per thousand at the yards. Brick were also made in considerable quantities in the western part of the town about fifty years ago, using the clay of the valley of Wilmot brook, about a mile northwest of the meeting house, but the manufacture has been abandoned at that point for over twenty years. The yards have been turned into meadows and pastures, and only the deep pits remain to indicate the place.

|

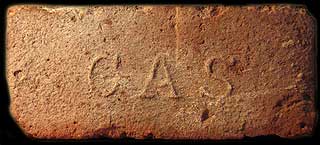

Shultz Bros.

Estate of C. A. Shultz East Kingston, NY (1899) 6 machines (found at the brickyard site)

For some history and pix of the site, visit our |

Singack Brickyard Singack (Little Falls/Wayne), NJ (Morris Canal area) (Found in Saddlebrook, NJ by Ken Findlay of Findlay Landscaping LLC)

NY Times

NY Times

|

Staples Brick Company

East Kingston, NY (1905) 3 machines Alvah S. Staples, Malden, NY (1899) 3 machines (found in Pelham Manor and Rosendale, NY)

==========

HudsonValleyRuins.org ========== STAPLES brick are among several brands that were used in the legendary ROSENDALE cement works.

Cement Kilns in "Willow Kiln Park," Rosendale, NY, March, 2007

Century House

"The Cement That Built America" Rosendale Natural Cement Historic District "Bricks from the Lawrence Cement Company and the F.O. Norton Cement Works"

Hudson Valley Ruins

|

Star Brick Company of New York Montrose, NY (1889) Found in the ruins of the Centennial Hose Firehouse, Peekskill, NY ========== From Westchester County Incorporation Records, 1876-1914:

-Avery, James D., The Star Brick Company of New York, Manufacturing, milling, refining, Cortlandt 10/23/1889 Nathan Peck and Robert Martin also operated The Peck & Martin Brick Company which may also have used a "Star" logo.

|

I.L. Stiles & Son Brick Co. North Haven, CT (1892 - 1957)

Listed in an 1897 New Haven Business Directory:

Stiles + Hart

This script version was manufactured by Stiles & Hart.

(S + H brick can be found throughout the Northeast. We've spotted them at the Fire Island Lighthouse, Long Island, NY;

Posted by: Kurt Bauer

I sent the following message to Jim Graves of the International Brick Collectors Association, and received the following response: Dear Jim: While attending the Stiles Family reunion in Pittsburgh two weeks ago the question came up re: the bricks. I then did a search through the internet & found a company Stiles & Hart Brick Co. in Bridgewater MA and contacted them. They said that they have been in business since 1892, making bricks with "STILES" on them distributed throughout Conn, Mass, etc. They were a Connecticut Co., originally Stiles Co. & were bought out by Hart Co. three generations ago. They were supposed to send info to me but I have not received anything yet. I am trying to confirm this information. Any additional info would be appreciated. Dear Kurt, Thank you for the inquiry. As you noted the Stiles brick company goes back a few years. I.L. & H.H. Stiles operated in North Haven,CT 1875-1879 I.L. Stiles & Son Brick Co. 1892-1957 Stiles & Hart 1913-present (had several plants but now only the Bridgewater remains) I don't know if the Stiles & Son and Stiles & Hart are the same business (it sometimes happens that both names are listed for some time to confuse researchers like us) Stiles & Hart still makes brick marked S + H There are at least two different Stiles bricks. One is marked in script and the other in block letters. Both are raised letters in a recessed panel (called a frog). I would greatly appreciate copies of anything that Stiles & Hart sends you to add to our library holdings. If you like, I'll see if any of our members has extra Stiles brick. Sincerely, Jim Graves 3265 Hood Ct. Wichita,KS 67204 ==========

Bridgewater Brick CompanyFrom "The Stiles + Hart Plan," Natural Resources Trust of Bridgewater re an abandoned S + H site:"This 75-acre site was an agricultural fairground with a grand exhibition hall from c1820- 1875. In 1895, a local teacher, Mr. William Basset, Sr., purchased the land and founded the Bridgewater Brick Company. The company mined clay and produced bricks on the site. In 1913, Stiles & Hart Brick Company purchased the operation. Due damage to buildings in the hurricane of 1938, brick production ceased, but clay mining continued until after World War II. The site has been recommended as a National Register District by the Massachusetts Historical Commission. The four large ponds and the many smaller ponds along with the mounds of defective bricks up to eight feet in height give further historical evidence of this earlier activity. A neighbor now owns the private property that was the site of the former grand exhibition hall, and later a shoe factory.

To the west of the property is Broad Street (Route 18), a busy state road with a park entrance adjacent to the Town River. Many local residents, however, use the wide trail that crosses a private five-acre plot midway along Broad Street.

To improve the appearance and safety of the trails, bricks dumped by the trail should be removed; there is a large quantity of bricks near the end of the sewer easement.Useable bricks should be saved and used where appropriate in walkways, at the future parking area at the old town garage or as part of a brick historical designation that highlights historical features that are connected with the brick manufacturing history of the site.

Many of the abandoned bricks on site could be used to mark viewing points for historical features connected with the brick making industry such as the remains of the brick- making factory, the site of the kiln, the excavated ponds, and the location of the railroad spur. A small brick patio could exist at each of these locations enabling visitors to locate themselves on the map.Information maps give details of the site history, the brick making process, the ecology of the site and its surroundings." ==========

The Stiles Clay Pit of HamdenThe Quinnipiac Valley has extensive deposits of red clay, laid down between 11,000 and 12,000 years ago during the close of the last glacial period. Our region of Connecticut is famous, in fact, for its New Haven clay, which has been quarried for brick manufacture for more than 125 years. Up until the last several years this area was the site of a major quarrying operation. Clay pits were dug in the meadowlands bordering the Quinnipiac River, and the Stiles Corporation brickyards with their kilns were located nearby. Many of the earlier buildings in town were built of the locally manufactured bricks. Bordering the marshes along State Street, from New Haven to North Haven, the deposits of clay lie between 15 and 20 feet below the present land surface and well below sea level. The clay varies in thickness, due to differential erosion of the deposits more than 7,000 years ago, but various estimates of the thickness of the clay range from a minimum of 3 to 20 feet to a maximum of more than 75 feet. Close examination would reveal that the clay actually is made up of many distinguishable layers, called varves. Each varve was laid down during post-glacial time in the course of one year, the clay material that precipitated out in the winter freezes being different in appearance from the summer silts. For this reason it is known as varved red clay. There is reference in the literature to a count of 364 varves in one 17 foot thick section of exposed clay. In order to get to the clay, workmen had to remove the covering layers of material, which were deposited in more recent millenia. In the 1800s and early 1900s they dug manually; steam shovels were used later. The upper deposits are the ones of interest to the paleobotanist, because they are rich in compacted, semi-fossilized Plant matter. The outdoor laboratory of the Stiles clay pits has received the attention of the Yale scientific community since the early 1900s. As quarrymen labored for the important clay deposits, gealogists and ecologists studied the exposed overlying strata and their contents. At certain depths the following macroscopic plant matter has been uncovered: leaves of many types, twigs, nuts and seeds, cones, stumps and lags, some of them quite sizable, and remains of salt marsh plants and peat. Microscopically, many types of pollen are found. A cursory examination of the sediment is all that is needed to realize that there are several distinct layers present and that the geological conditions under which organic and inorganic materials were deposited varied. A summary of the geological events of this region follows. Between 10,000 and 15,000 years ago, in late-glacial and post-glacial times, a freshwater lake had formed at the mouth of the Quinnipiac River. As the glacier slowly retreated, a mass of ice broke off, became stagnant, and dammed up river water as well as its own melting water. These deep, muddy waters were responsible for the thick buildup of the clay. During the gradual warming period which ensued, the glacial ice eventually disappeared and the ponded waters were restored to a river system. There may have followed several thousand years during which silt and sands were deposited, only to be eroded away along with some of the underlying clay. Today a four foot layer of coarse sandy material lies immediately above the red clay. It has been dated, through radiocarbon testing of an entrapped log, to 7,000 years before present. There is no indication that this sand was deposited under salt water conditions. Rather, the freshwater river, moving at a rate fast enough to carry along fairly heavy sand particles is responsible for these deposits. Logs and stumps are found throughout this layer and also in the four foot layer of finer gray sand above, apparently deposited by more slowly-moving waters. There are also layers in which nuts and seeds are common, or thicknesses of matted leaves. These important fossil-bearing strata are now located 10 to 18 feet below the surface. It is this material which shows the early stages of fossilization. Found in this basal alluvium are the remains of wood, leaves, and reproductive structures of beech (the predominant species of tree), hemlock, hickory, pine, oak, and buttonwood. The logs present are not in their natural positions but instead were washed into the area, where they sank and became buried. The remnants of shrubs and of a number of herbaceous plants are also contained in the sandy layers. These findings are suggestive of a shallow stream or river environment, surrounded by a beech forest. In the upper portion of the fine sandy layer maple is found, indicating that the region changed over to a freshwater marsh for a period of time. A log in this upper layer of sand is radiocarbon-dated to 3560+80 years B.P. All material lying above the sand is peat, and it forms a layer approximately 10 feet thick. The peat contains remains of Spartina and Phragmites, grasses. This is salt water tidal marsh vegetation, and it indicates that for the last 3,500 years the region was at sea level, and that the tidal conditions had killed off all freshwater trees, shrubs, and herbs. The peat accumulated slowly from succeeding growths of marsh grasses. The balance between sedimentation and submergence of the land (or a rising sea level) had shifted to conditions which persisted until recently. When man intervened and constructed a dike and railroad bridges downriver, the now-protected area changed over to a freshwater marsh habitat, characterized by the growth of Typha (cattail). It is now referred to as an estuarine freshwater marsh. The same species growing 3,000 to 7,000 years ago in the area of the Quinnipiac River are found in the surrounding area today. A walk through the thickets that lie south of the clay pit turns up wild grape vines and raspberry canes, whose seeds are preserved in the clay pits. Beech trees, maples, and oaks also make up the thickets. Today the New Haven clay is no longer quarried in Stiles clay pit. A series of quarried and abandoned pits are found to the east of State Street, filled up with water. The most recent site to be dug is now being used for landfill, meaning that it is a garbage dump. It will eventually revert to marshland or be filled in above sea level. Presently below sea level, the pit is protected by a dike from the nearby tidal waters and it is continually being pumped of water that seeps in from the uplands, just as it was pumped during the brickmaking period. One expanse of the pit remains where a 14 foot high cross section of the peat and sandy layers can be seen. The brick clay now lies out of view. Beinecke, Frances, and Siccama, Thomas, The Stiles Clay Pit, Hamden, Connecticut, Connecticut Natural Areas Inventory No. 157, January 1973. A good review of the natural history of Stiles clay pit and an analysis of the past, present, and future uses of the pit. Longwell, Chester R., and Dana, Edward S., Walks and Rides in Central Connecticut and Massachusetts. New Haven: Tuttle, Morehouse and Taylor, Co., 1932. (Reprinted by The Shoe String Press, Inc., 1961.) This book is one of the real classics, and it belongs on any nature lover/outdoors-type’s bookshelf if you can find a copy! The several pages on Stiles clay pit are easy and enjoyable to read (some assistance being required on the geology information). (SOURCE: Yale.edu

|

Streeter & Hendricks

East Kingston, NY

|

Stiles & Reynolds Brick Co. Christian Lane Berlin, CT (found in Newtown, CT by Nancy Nouss-Brown) For more info on Berlin brickmaking, see B B Co |

Sutton & Suderly Brick Co.

Coeymans, NY (1899) 4 machines

COEYMANS, N.Y. -- This village is practically under martial law tonight. The Second Battalion of the Tenth Regiment, sent from Albany, twelve miles away, to quell disturbances which broke out to-day among Italian laborers in the great brick yards here, is guarding the streets as well as the brick plants on the river. Read the full story HERE. ==========

Ravena Coeymans Historical Society (www.coeymanshistory.org/files/winter2007.pdf)

The Hudson Valley was once home to 88 brickyards. Some of these early brickyards were Sutton & Suderly, Roak Hook, Hardwick & Walsh, Ziegler & Ziegler, Sutton & Sinsabaugh, Adamo's and Mayone's.

|

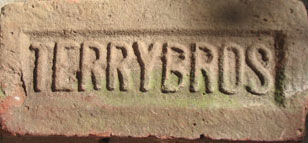

Terry Brothers

(found at or near the brickyard site, "Steep Rocks," East Kingston, NY ) (accessed by boat, the land approach is private property)

(found in Pelham Manor, NY) Kingston (Rondout), NY (1902) 3 Machines Steep Rocks (Ulster Landing/East Kingston), NY (1910) 8 Machines

The TERRY brand was made from mixed blue and yellow clay. The TERRYBROS brand was made from blue clay alone. The Terry yards were founded in 1850 by David Terry. At his death in 1869, the business was taken up by his sons Albert and Edwin. In 1902, Edwin retired and the concern was incorporated as The Terry Bros. Co. Albert was elected president, Jay Terry vice-president and David Terry, secretary and treasurer. (SOURCE: Hall, Charles Ellery, The Story of Brick)

The Terrys are credited with being the first to attempt burning brick with coal.

(SOURCE: deNoyelles, Daniel, Within These Gates, p.263)

|

Francis A. Timoney

Dutchess Junction, NY At the age of 23 Francis Timoney came to the US where he worked at the SM Dykeman brickyard in Verplanck, Westchester County NY. After 3 years he had been foreman for 2 years, and began to work for shares. Two years later he purchased half interest in the company. Four years later he bought the second half. Here is an 1891 map of Verplanck by F. W. Biers showing the land owned by "F. Timony" (sic). In 1886 he purchased the Dutchess Junction properties. There was one yard in working order, eventually there were three (1/4 of million bricks per day!). He owned 2 barges that brought the materials up and down the Hudson River.8 In the 1900 Census for Fishkill, Dutchess, NY,

Francis Timoney is listed as: In addition to the brickyards, Timoney built and owned the Dutchess Manor House. He also built a Roman Catholic Church for his workers in Dutchess Junction (nicknamed Timoneyville) and named it after his patron saint (St Francis). Timoney was the Third Francis in his line and there have been many more since.2 On July 14, 1897 two of the three Timoney brickyards were all destroyed by a dam breaking. "The brick-making plant, wagons, carts &c., were swept across the railroad track into the river. At the northern yard were sixty arches of 'green' brick, 45,000 in each arch. The water softened these and let the whole down in a mass of clay. A twelve-arch kiln was burning. The flood put out the fire and practically ruined the brick. Mr Timoney will be unable to resume operations in the two yards this year. The yards had a capacity of 24,000,000 bricks a year and Mr. Timoney's loss is $25,000. The adjoining brick yard of Hammond & Freeman was damaged to the extent of $5000.1" The Timoneys were not able to fully recover. Eventually, they sold the Manor House and it is now a catering facility. The church closed but eventually re-opened as a nursing home. From Fred Rieck: "The brand was "F.T." for Francis Timoney, or his son Frank. Francis owned the yard first (and a grocery) and Frank became the listed manufacturer after 1887. He remained listed as a manufacturer until 1905 when both the Beacon City Directory and the 1905 NY State Quarry and Mining Industry Report list his wife, Margaret Timoney, as a Dutchess Junction brick manufacturer." |

Henry Toppin

Ulster Landing/East Kingston, NY (found at or near the brickyard site, accessed by boat, the land approach is private property) |

Towey Brick Company

Poughkeepsie, NY (found in landfill, Arlington, NY) A note from Janet Towey Mann: "My father, William J. Towey owned Towey Brick and Tile Co. in 1920's and 30's. How exciting to find a photo of one, as I have been looking for years for this brick. Thank you." |

Tri-County Brick Company

Moonachie, NJ (1957-1964) (SOURCE: Jim Graves in "Brick Manufacturers of the United States" citing the 1957 Directory of The Structural Clay Products Institute.) |

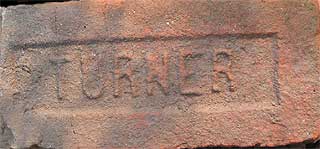

N.E. Turner

Port Ewen, NY (1905) (found at the brickyard site, now:   George H. Freer Memorial Park) |

Tuttle Brick Company

Middletown, CT 1842-c1940 Webmaster Note--we received this item in January '07: My Great X4 Grandfather, founded the Tuttle Brick Company in Middletown, CT. Here's a history of it:

==========

From The History of Middlesex County 1635-1885

========== Read more about TUTTLE on BrickFrog's Blog |

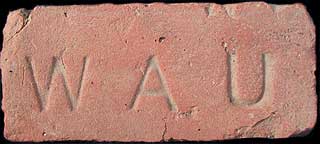

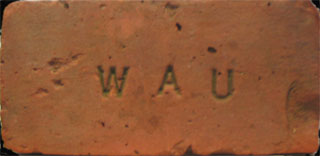

William A. Underhill

Croton Point, NY (1899) 8 Machines (found at the brickyard site, now Croton Point Park) (IXL = "I excell") Notes from Sarah Gibbs Underhill "Tales From Croton Point." Early Photos of the Underhill Yard. |

George W. Washburn & Company

Catskill, NY (found at the brickyard site, now Catskill Middle School.)

Click here to see an old engraving (L.R. Burleigh, Troy, NY 1889) of the Catskill site.

|

Washburn Bros.

Glasco, NY (found by Ken Findlay, Findlay Landscaping LLC)

The brick industry grew in the 1880s when Washburn Brothers and Empire State Brick Company opened their brickyards. At one point, the area boasted over six brick factories (see below), a ferry service, a school, churches and several saloons. Bricks were sent down the Hudson River by barge to furnish the construction of America's cities. During the depression the brick business languished. One of the Washburn brothers committed suicide. All the workers were called in by the remaining brother and told, "Business is bad. If you stick with me you won't lose your job but your wages will be reduced until we can see this through. If you can't stick with the company you're free to go and find other work. Many left the brickyard and even Glasco to find other work. Many went to Athens and Hudson to work on other brickyards and in the cement plants.

(Sources: italiangenealogy.tardio.com

|

Uriah F. Washburn & Co.

Grassy Point (Haverstraw), NY (1863) 11 machines (found in the Hudson River at Haverstraw)

"The Washburn brickyard was a part of Haverstraw's once flourishing brick industry, which lasted from 1800 to 1941. In 1861, Uriah Washburn was one of the first in Haverstraw to supply money for the families of the volunteers in the Union Army." ========== From "Sloops of The Hudson" by: William E. Verplanck and Moses W. Collyer G.P. Putnam's Sons, New York & London, 1908: "The Uriah F. Washurn, built by Jacob Woolsey at Tompkins Cove in 1866, was undoubtedly the best example of these modern schooners. Her captain was James Monahan, who sailed her for 17 years, and is now first pilot of the steamer City of Newburgh of the Central Hudson Steamboat Co. This schooner was built for the Washburn Bros., brick-makers of Glasco-on-Hudson, and she now hails from Perth Amboy, N. J. Her carrying capacity was about 200 tons." ========== From: Portrait and Biographical Record of Rockland and Orange Counties New York, Chapman Publishing Co., 1895: DENTON FOWLER, JR. Few citizens of Haverstraw have a more thorough knowledge of the brick business than the subject of this notice, who has devoted his entire active life to the occupation, and has gained a comprehensive knowledge of every department of the work. He is connected with the firms of U. F. Washburn & Co., which was organized in 1883; D. Fowler, Jr., & Co., which has existed since 1880; and Washburn & Fowler, which was established in 1889. The yards of these companies are situated between Haverstraw and Grassy Point, and have an aggregate capacity of forty-five million brick, furnishing employment to as many as four hundred and fifty men. The same parties compose all three companies, Mr. Fowler's associates being H. C. Blair and Mordecai F. and Lucian H. Washburn. In Haverstraw, which has been his life-long home, Mr. Fowler was born October 25, 1856. His education was begun in the public schools of this place and afterward carried on in Packard's Business College. While still a boy he began to work in his father's brickyards, in which way he became familiar with every department of the brick business. In 1880 he embarked in business for himself, and organized the firm of D. Fowler, Jr., & Co., which has since carried on an extensive trade in the brick industry. He devotes his attention to the manufacture of brick, and allows no outside matters to interfere with his chosen work. With the firms of U. F. Washburn & Co. and Washburn & Fowler he occupies the positions of Secretary, Treasurer and bookkeeper, and he has also been superintendent of one of the yards for some time.

The attractive residence of Mr. Fowler, which is the old Judge Suffern

homestead on Allison Avenue, is presided over by the accomplished lady who

became his wife December 19, 1894. She was Miss Lucretia, daughter of Samuel

Snedeker, a brick manufacturer of Haverstraw. Though a Democrat in national

politics, Mr. Fowler takes little interest in public matters and has never

sought nor been willing to accept official positions, preferring to give his

attention to business affairs. With his wife, he holds membership in the

Presbyterian Church.

|

Uriah F. & J.T Washburn & Co.

East Kingston, NY(1899) 5 machines (found at the brickyard site, now Robert E. Post Memorial Park)

He married Perina Costa in 1920, and lived in a house which they rented from the owners of Washburn's brickyard in the town of Ulster, which my Grandmother always called "East Kingston". It was only a few houses up from where she had lived with her family before marrying, and was a large, new 6 family house. Her sisters Luisa and Lil were on the same floor as she and Guido, and three other families lived upstairs. According to my grandmother, this was a wonderful house. Rent was $5. per month, and rent was waived completely during the winter months when the brickyards closed. When electricity was installed in 1925, it added another $1.25 to their rent. Winters must have been a financial drain on the couple. Around 1925, Guido took his wife and children to N.Y.C to earn money shoveling snow during the cold months. This arrangement was very difficult however, and they only tried it one season. It was also about this time that the Washburn brickyard was meeting increased competition from newer brickyards 15 miles up the river in Malden. These yards were more modern and were opened year round. The Washburn brickyard closed in 1925, and Guido and Perina moved their family to Malden. My grandmother Perina said she cried for two hours when she saw the dilapidated house they were to move into in Malden. The owner of the brickyard (Staples) did not keep their houses nearly as nice as those in Washburn's brickyard. Never the less, they persevered and eventually fixed the house up. Perina boasted that other than the owner of the brickyard, her family was the first to have running water installed in their home. Apparently the foreman, a Mr. Street, liked the hard working Guido and convinced the yards owner to install a pump for the family. In 1934 the depression was in full swing. The brickyards started closing and Perina and Guido moved their four children to Poughkeepsie N.Y. Guido officially retired from the laborers union in 1955 at the age of 65, but continued working for private contractors until he was 80.

|

Uriah Washburn & Denton Fowler

Roseville (Haverstraw), NY (1880 - 1906) (Yard #21 in 1896) (found on the Upper West Side, NYC)

DENTON FOWLER, President of the People's National Bank of Haverstraw, and one of the oldest and most extensive brick manufacturers in the Hudson Valley, was born in Orange County, four miles north of Newburgh, December 6, 1825. He is a son of Levi Q. Fowler, who, though a native of Ulster County, was reared from early boyhood in Orange County, and there married Lucretia, daughter of Solomon and Mary Purdy. About 1843 he and his wife moved to Newburgh, where he continued to follow the occupation of a brick-maker, owning a yard five miles from the city. After some years spent in Newburgh, he went to Haverstraw, where his death occurred at the age of about sixty three. His wife also passed away at that age. In boyhood Denton Fowler was employed in his father's brickyard, where he gained a thorough knowledge of the business. At the age of eighteen he went to Cold Spring, where he worked in a brickyard by the month. From that place, in 1843, he came to Haverstraw, joining his elder brother, Mordecai L., who worked in a yard at Grassy Point. In 1845 the latter started in the brick manufacturing business, and Denton purchased an interest in the enterprise. At that time there were only about six men engaged in the business in this locality, and the majority of these used hand machines, only one having a power machine. Their yards were situated near the village, and they gave employment to about thirty men, with an output of three and one-half million of brick. Their products were conveyed by sailboats to New York, where they realized from $3.50 to $4 per thousand in the sale. In 1847 the brother died, and Denton became sole proprietor of the yard, since which time he has conducted the business, being at present the oldest surviving brick manufacturer along the Hudson River. After having for thirteen years devoted his attention to the management of this yard, Mr. Fowler leased another yard further south, and there he continued until quite recently. With his brother-in-law, Uriah Washburn, he bought the Garner property, half-way between Haverstraw and Grassy Point, and there his son, Denton, Jr., carries on a brick business. He and another son, Everett, under the firm name of D. Fowler & Son, are operating a yard which has a capacity of nine million, and furnishes employment to sixty or seventy men from May to November. In partnership with Ira M. Hedges, Uriah Washburn and George Smith, he purchased the Derbyshire manufacturing yards, and the firm was subsequently merged into the Excelsior Brick Company. His interest in that enterprise is now held by his son Everett. With the history of the People's Bank, the name of Mr. Fowler is indissolubly linked. He assisted in its incorporation, was a Director from the first, and at the death of Mr. Washburn was elected its President, in which position he has since officiated. His real-estate interests are extensive, and include the ownership of considerable property in Nyack as well as Haverstraw, where he has improved several pieces of land and put up buildings. Near New City he has a farm, the management of which he superintends.

In 1850 Mr. Fowler married Miss Catherine E., daughter of John E. Hogencamp,

for many years Clerk of Rockland County, and at one time owner of the farm now

belonging to Mr. Fowler. For years before his death he was blind, an

affliction which prevented him from engaging in business or farm pursuits. His

closing days were spent in New City. His wife was Gertrude Blauvelt, a member

of one of the oldest families of this locality, and whose ancestors settled

upon the farm now owned by Mr. Fowler. Politically our subject is a Democrat,

but while participating actively in public affairs, has never desired official

positions. In religious belief he is identified with the Presbyterian Church.

He and his wife are the parents of the following-named children : Gertrude M.,

Mrs. Holly DeBaund, who died leaving two children that are now with our

subject; Lucretia, wife of Henry VerValen, Cashier of the People's Bank;

Everett and Denton, who are engaged in the brick business; Sarah, Mrs. George

Ellison; and Fannie, wife of George Archer.

|

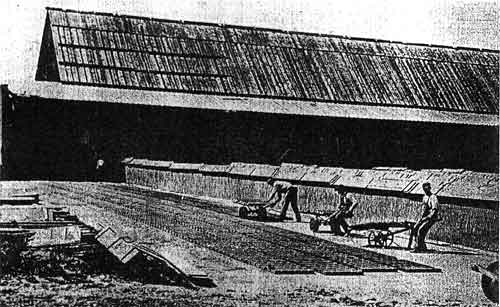

WEST BARNSTABLE BRICK COMPANY

A recent addition to our collection from a brickyard with a fascinating history.

From "History of Barnstable County, Massachusetts,"

Brickmaking On Cape Cod

(Photos courtesy Whelden Memorial Library, W. Barnstable, MA)

A History of the West Barnstable Brick Company

|

WETTERAU

Poughkeepsie, NY (found in landfill, Arlington/Poughkeepsie, NY)

|

UnidentifiedIf you can help ID these, CONTACT US

|

|

FYI World Media.com WIND-POWERED Web Site Hosting For YOUR Information on the World Wide Web © 2005 - 2022 D.S. Bayley

Hudson River Brickmaking |

Brick History/How Bricks Were Made ← HUDSON RIVER & NEW ENGLAND BRICK COLLECTION: A–L

|