The Innovators:

VerValen, Wood & Strickland

Richard VerValen

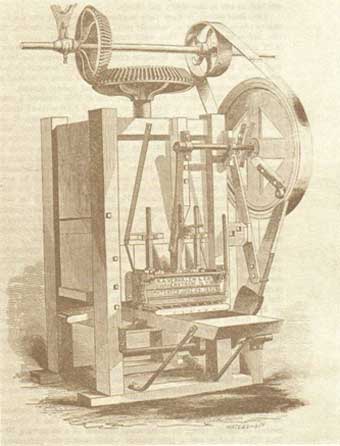

Brickmakers were confounded by the problems they encountered with the oftentimes irregular shape of the building blocks, which at that time were made almost entirely by hand. A few rudimentary tools had been introduced to help streamline production and in 1830, Nathaniel Adams of Newburgh and Cornwall, NY, invented a moulding machine. However this required human or animal labor to operate. The real break-through came in 1852, when Richard VerValen developed his brickmaking machine. This connected to a steam-powered drive shaft called a "power-line."

VerValen, who knew the industry and had "an inventive mind," pondered the dilemma for a time, according to the late historian, author and area resident, Daniel deNoyelles, in his book, "Within These Gates."

Before VerValen invented his machine in 1852, the clay was forced into the moulds by hand, and therefore had to be rather soft - and when the bricks were dumped out of the moulds, many became misshapen. VerValen's machine made it possible to use stiffer clay.

Quoting from deNoyelles:

"..the VerValen machine forced the raw clay into the moulds with a machined packer. The moulds held six brick paralleling each other. Under this newer method a stiffer clay could be used, which made a brick more square. The moulds were drawn by hand from a revolving sander where the iron oxide was added to the flour-like moulding sand. This dusted the insides of the moulds and allowed the soft brick to slip easily to the surface on the drying yards. Of course the filled mould were first 'struck off' by a two-handed knife about two feet long. This made the brick smooth on the exposed plane. This knife was called the moulder's strike'."

"The tempering of the mixture was effected back of the press by a steel shaft pinned with steel knives which extended into the raw clay, sand, and coal dust which had been conveyed above the press by a chain and bucket elevator."

"Red coloring was added to the outside of the newly-moulded brick by adding iron oxide to the moulding sand in the patent sander ca. 1885. Before that time, brick had been burned in their raw state, resulting in a light pink color with a whiteish tint at times. With the use of red ochre, as some oldtimers called it, the hard-burned brick had a deep red, and in some places, a rich purple hue."

Another machine was invented in 1874 to automatically 'sand' the moulds, so that it could keep up with the VerValen moulding machine.

A Closter, NJ native, VerValen lived in Rockland County, NY as a child. He then left for upstate New York before returning to Rockland (Haverstraw) in 1848, where he worked manufacturing stoves and plows in his foundry.

According to legend, it was in the middle of a Sunday church sermon that VerValen had a breakthrough and came up with the machine design. He patented his machine in 1852 and, its principles were "so workable and so novel to brickmaking" that they were used until a more advanced machine, incorporating some of his original ideas, was developed in the 1920s.

James Wood

In 1828 brickmaker James Wood discovered that 'culm' - fine coal dust - added to the mixture reduced burning time for a kiln by one-half, from FOURTEEN DAYS to SEVEN. He patented it in 1836:

'Be it known that I, the said James Wood, have invented a new and useful improvement in the art of manufacturing bricks and tiles. The process is as follows: Take of common anthracite coal, unburnt, such quantity as will best suit the kind of clay to be made into brick or tile, and mix the same, when well pulverized, with the clay before [it] is moulded; that clay which requires the most burning will require the greatest proportion of coal-dust; the exact proportion, therefore, cannot be specified; but, in general, three fourths of a bushel of coal-dust to one thousand brick will be correct. Some clay may require one eighth more, and some not exceeding a half-bushel. The benefits resulting from this composition are the saving of fuel, and the more general diffusion of heat through the kiln, by which the whole contents are more equally burned. If the heat is raised too high, the brick will swell, and be injured in their form. If the heat is too moderate, the coal- dust will be consumed before the desired effect is produced. Extremes are therefore to be avoided. I claim as my invention the using of fine anthracite coal, or coal-dust, with clay, for the purpose of making brick and tile as aforesaid, and for that only claim letters patent from the United States.

JAMES WOOD.'

Dated 9th November, 1836.

Wood, an Englishman, came to Ossining, NY in 1814 but found little clay there so he leased a yard across the river (from Daniel deNoyelles) in Haverstraw and established his first brickyard in 1815. Later he invented a machine for tempering clay.

There also was a "Wood" brickyard in Tarrytown, NY:

"During the mid-1800's brick makers took advantage of the clay deposits in the (Sleepy Hollow/Tarrytown) area. In 1885 Wood Brick Yard sold its property at the foot of Beekman Avenue to the Rand Drill Company, in what would later become the home of several automobile manufactures. In 1899, on the south side of present day Kingsland Point Park, automobile making began with the Mobile Company of America producing the Stanley Steamer. This was succeeded by the Chevrolet Company and then the start of the General Motors Company in 1915. In 1996 after having assembled some 11 million vehicles General Motors closed down and dismantled all of its buildings as required by local law." Ed. Note: The site is now being developed for condominiums.

(https://www.scenichudson.org/rivercomm/riverfronts/gmhistory.htm)

Three generations of Woods: James, Samuel and George all worked at the Tarrytown yard. Here's a biographical sketch of George Wood:

GEORGE S. WOOD. On an elevated terrace near Tomkins Cove, commanding a

beautiful view of the river and surrounding country, stands the home of Mr.

Wood, and here he has resided since 1864. His principal business in life has

been the brick industry, though he has other interests that are important and

valuable. In everything pertaining to the advancement of Rockland County he

maintains a deep interest, and his co-operation is always to be depended upon

in matters tending toward the general welfare.

The ancestry of our subject is traced to England. His grandfather, James Wood,

emigrated from that country to America in 1801, and be-came one of the pioneer

brick manufacturers of this section of country. Prior to leaving his native

land, he learned the brick-making business, and he was the first in this

locality who utilized coal dust in its manufacture. The immense business of

this character now carried on at Haverstraw and in the vicinity is the growth

of the beginning made by him. Our subject's father, Samuel Wood, was born in

Colchester, England,and when only five years of age was brought to America.

His boyhood days were spent in this locality, and at a very early age he

became familiar with the brick business, which he followed throughout his

entire life, having extensive interests at Haverstraw and Tarry town. His

death occurred in r868, at the age of seventy-three.

The mother of our subject was in maidenhood Malvina Smith, and was born in

Rockland County. Her death occurred in Tarrytown at the age of seventy-six. Of

her twelve children we note the following: Mary is deceased; George S. is the

subject of this notice; Orlando is deceased; Mary Elizabeth is the widow of

George Gaylor, and resides in Stamford, Conn.; Caroline, Mrs. Caleb W. Horton,

is deceased; Theodore S. died at the age of thirty-eight; Martha Amanda died

in girl-hood; Henrietta is the wife of George Smith, of Tomkins Cove; Euphemia

died when three years old; Horatio Nelson was in the navy, under Admiral

Farragut, during the Civil War, and now makes his home in Haverstraw; Nellie

died at the age of forty-three; and Sophia, deceased, was the wife of Joseph

H. Vail, of Tarrytown.

In Haverstraw, January 31, 1823, the subject of this sketch was born, and

there the first eight years of his life were spent. He then accompanied his

parents to Tarrytown, where he remained until twenty-one years of age,

meantime attending the public schools of that place, and gaining a fair

education. Like his ancestors, he early gained a thorough knowledge of the

brick business, and in that industry he embarked at Tarrytown when twenty

years old. He continued to reside there until 1852, meeting with flattering

success in his ventures, but at that time he returned to Haverstraw, where the

twelve ensuing years were passed. In the fall of 1864 he came to Tomkins Cove

and took up his residence at the beautiful place he has since occupied. He has

extensive real-estate interests, not only here, but also in other places, and

is also interested financially in the Tomkins Cove Stone Company.

The political opinions of Mr. Wood are by no means undecided, for he is a firm

and loyal sup-porter of the Republican party, and uniformly votes that ticket.

In religious belief he is connected with the Methodist Protestant Church.

Personally of a genial, affable nature, he has won a host of friends in this

community, and is highly esteemed for his uprightness of character and

geniality of disposition. His marriage united him with Miss Laura P., daughter

of Calvin and Esther (Tuers) Tomkins, and they became the parents of a

daughter, Esther M., who died at the age of nineteen years.

(SOURCE: Portrait and Biographical Record of Rockland and Orange Counties New York

Containing Portraits and Biographical Sketches of Prominent and Representative

Citizens of the Counties.

New York and Chicago; Chapman Publishing Co., 1895)

David Strickland

David J. Strickland of Cleveland, OH, the Bronx and Beacon, NY, patented numerous brick-making inventions:

1911: Improved Brickmaking Machinery.

1920: Strickland Automatic Brick-making Machine.

1925: Low-Pressure Steam Brick Dryer.

Strickland is also credited with creating oven-sized brick and introducing the coloring of common brick in the New York market.

|